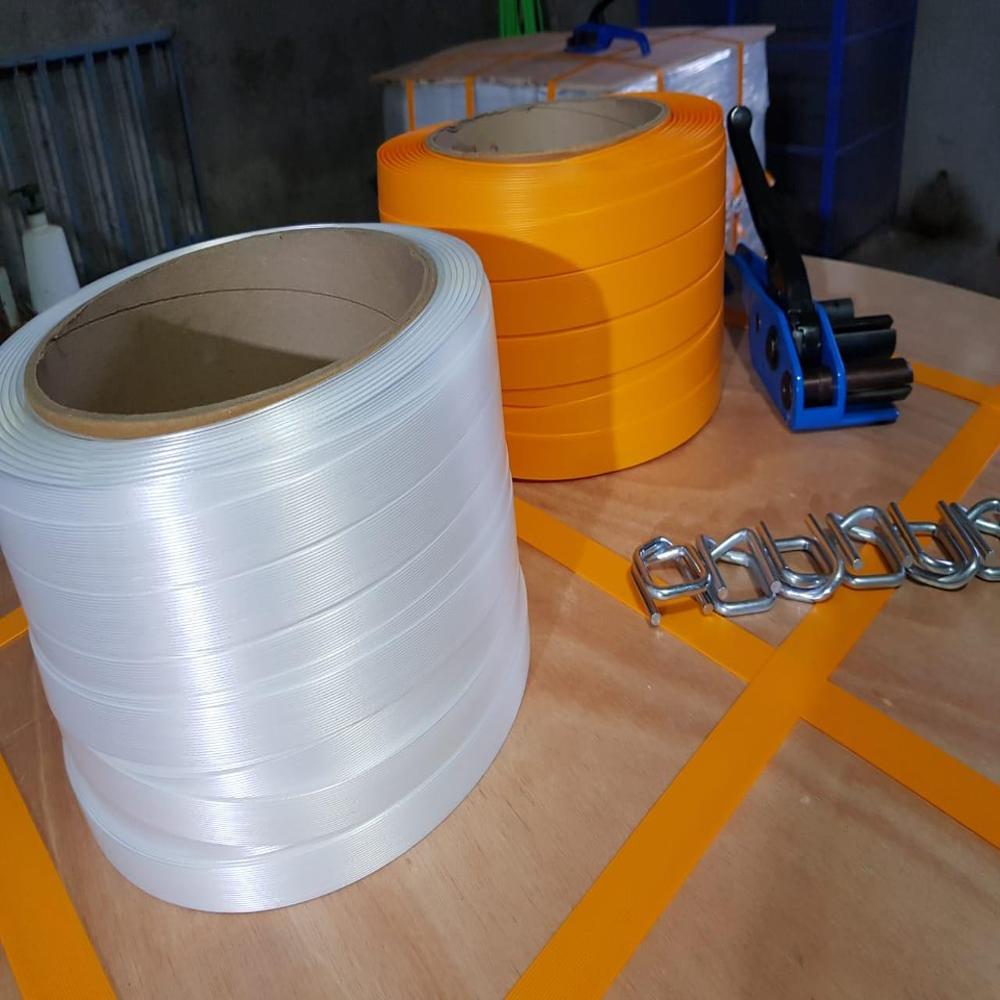

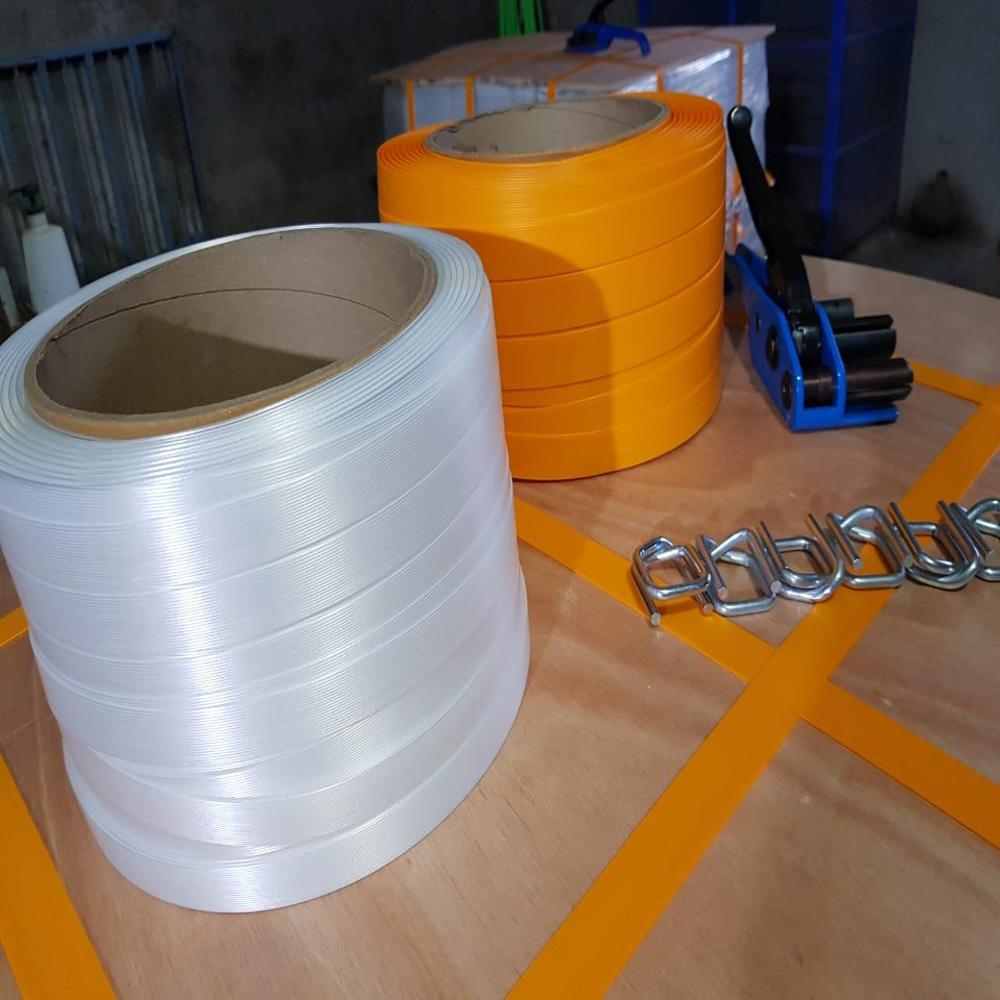

Galvanized wire tie buckle

Product Details:

- Feature ZINC COATED

- Material Stainless Steel

- Shape Oval

- Usage PALLATIZING AND BANDLING

- Hook Type Utility Hook

- Size 19MM

- Install Type JOINT THE STRAP

- Click to View more

Galvanized wire tie buckle Price And Quantity

- 10 Box

- 2.25 INR/Box

Galvanized wire tie buckle Product Specifications

- ZINC COATED

- Stainless Steel

- Utility Hook

- Oval

- PALLATIZING AND BANDLING

- 19MM

- JOINT THE STRAP

Galvanized wire tie buckle Trade Information

- MUNDRA

- Cash in Advance (CID), Cheque, Letter of Credit (L/C)

- 200 Box Per Week

- 7 Days

- No

- Within a certain price range free samples are available

- PALLATIZING AND BANDLING

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India

- ISO9001-2015

Product Description

GI Wire Buckle Strong, Reliable, and Corrosion-Resistant Strapping Solution

A GI Wire Buckle (Galvanized Iron Wire Buckle) is an essential component used for securing strapping materials such as Cord Strap, PET Strap, and Composite Strap during packaging, transportation, and storage. It acts as a fastening and locking device that ensures the strapping remains tight and stable around cargo, pallets, or heavy packages. GI Wire Buckles are widely used in logistics, warehousing, export packaging, and industrial load securing applications, offering superior strength, durability, and corrosion resistance.

1. What is a GI Wire Buckle?

A GI Wire Buckle is manufactured using high-quality galvanized iron wire that has been zinc-coated to protect against rust and environmental damage. The buckle is formed into a specific design that provides maximum grip and holding power when tension is applied. These buckles are specially designed to work with polyester composite straps, woven cord straps, or lashing belts, making them suitable for heavy-duty cargo packaging.

The unique self-locking mechanism of the buckle ensures that the strap does not slip or loosen under load, maintaining tight tension even during long-distance transportation. The galvanized coating enhances its life span, especially in humid or outdoor environments.

2. Key Features of GI Wire Buckle

-

High Tensile Strength:

Made from durable GI wire that can withstand heavy loads without deformation or breakage. -

Corrosion & Rust Resistance:

The zinc coating offers long-term protection against moisture and rust, making it ideal for outdoor and export packaging. -

Excellent Grip & Holding Power:

The buckle design ensures firm grip with polyester or cord straps, preventing slippage during transit. -

Reusable & Economical:

GI Wire Buckles can be reused multiple times without compromising performance, reducing packaging costs. -

Easy to Use:

The open design allows for quick threading and tensioning of straps with manual or pneumatic tools. -

Compatibility:

Suitable for use with Cord Strap, Composite Strap, PET Strap, and PP Strap, offering great flexibility in application.

3. Technical Specifications (Typical Range)

| Parameter | Specification |

|---|---|

| Material | Galvanized Iron (GI) |

| Surface Finish | Zinc Coated / Phosphate Coated |

| Wire Diameter | 3 mm to 8 mm (custom sizes available) |

| Type | Open Type / Closed Type |

| Tensile Strength | 400 1200 kg (depending on size) |

| Usage | Cord Strap, PET Strap, PP Strap, Composite Strap |

| Finish | Smooth, corrosion-resistant surface |

| Reusability | Yes |

4. Applications of GI Wire Buckle

GI Wire Buckles are widely used in industries and sectors where cargo safety and load stability are critical. Some common applications include:

-

Export Packaging: Securing goods for international shipping and containerized cargo.

-

Logistics & Transport: Lashing heavy-duty cargo, wooden boxes, and pallets.

-

Warehousing: Stabilizing stacked goods and storage materials.

-

Construction: Securing materials such as pipes, steel bars, and machinery.

-

Manufacturing Units: For internal packaging, product bundling, and material handling.

-

Agricultural and Farm Use: Tying down loads, agricultural equipment, and materials.

5. Advantages of Using GI Wire Buckles

-

Superior Strength:

Designed to withstand high tension and heavy loads, ensuring maximum security. -

Weather Resistant:

Zinc coating protects against rust, corrosion, and extreme conditions. -

Cost-Effective:

Long-lasting and reusable, reducing packaging expenses in the long term. -

Non-Slip Design:

Prevents strap movement, ensuring stable packaging during handling and transport. -

Compatible with Various Straps:

Works perfectly with polyester, composite, and cord straps. -

Eco-Friendly Solution:

Reusable and recyclable, contributing to sustainable packaging practices. -

Customizable Sizes:

Available in multiple wire thicknesses and buckle dimensions to suit diverse applications.

6. Types of GI Wire Buckles

-

Open Type GI Wire Buckle:

Most commonly used; allows easy strap insertion and tightening using tensioners. -

Closed Type GI Wire Buckle:

Provides extra holding strength for heavier loads and secure applications. -

Phosphate Coated Wire Buckle:

Offers enhanced friction grip between strap and buckle; preferred for polyester cord strapping. -

Galvanized Steel Buckle:

Provides superior corrosion resistance for outdoor and export applications.

7. Why Choose GI Wire Buckle for Strapping?

When securing heavy cargo or valuable goods, GI Wire Buckles ensure that the strapping stays firm and stable. Compared to plastic or non-galvanized buckles, they offer:

-

Higher load-bearing capacity

-

Longer lifespan due to zinc coating

-

Enhanced grip with woven and composite straps

-

Compatibility with manual and automatic strapping tools

-

Resistance to temperature and humidity variations

This makes GI Wire Buckles a preferred choice in industrial packaging and international shipping where load safety cannot be compromised.

8. Industries That Use GI Wire Buckles

-

Logistics & Freight Forwarding

-

Manufacturing & Engineering

-

Automotive Packaging

-

Steel and Metal Industry

-

Construction & Infrastructure

-

Timber and Lumber Packaging

-

Textile and Paper Industry

-

Agricultural and Chemical Transport

These buckles play a vital role in ensuring cargo safety, preventing movement or shifting during handling, shipping, or long-distance transportation.

9. Packaging and Supply Options

GI Wire Buckles are usually packed in cartons or bags for convenience and protection. Bulk supply options are available for industrial users. They can be ordered based on:

-

Wire thickness (3mm to 8mm)

-

Quantity per box or carton

-

Type of coating (Galvanized / Phosphate)

-

Custom branding or labeling (for OEM supply)

10. Conclusion

The GI Wire Buckle is a small but essential component that plays a crucial role in the safety and stability of cargo during packaging and transportation. With its galvanized finish, high tensile strength, and reusability, it provides a cost-effective, durable, and dependable strapping solution for various industries. Whether used for cord strap, composite strap, or PET strap, the GI Wire Buckle ensures that every package is securely fastened and protected during transit.

By choosing high-quality GI Wire Buckles, businesses can enhance packaging efficiency, improve cargo safety, and reduce overall costs making it the ideal fastening choice for heavy-duty strapping and export packaging needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+