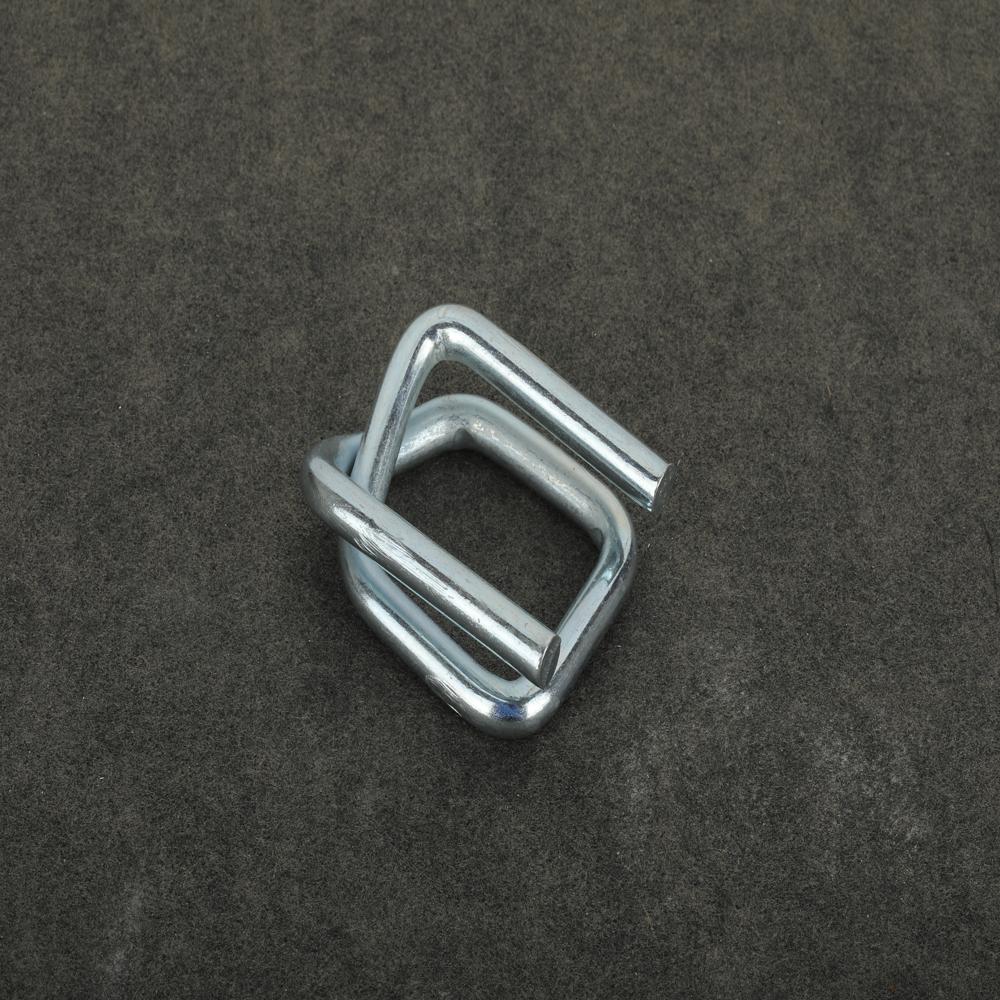

Industrial cargo buckle

Product Details:

- Feature zinc coated

- Style box packing

- Material Stainless Steel

- Shape Other

- Usage box packing

- Hook Type Utility Hook

- Size 16mm

- Click to View more

Industrial cargo buckle Price And Quantity

- 10 Box

- 8.0 INR/Box

Industrial cargo buckle Product Specifications

- Other

- Stainless Steel

- Utility Hook

- box packing

- zinc coated

- 16mm

- box packing

Industrial cargo buckle Trade Information

- mundra

- Letter of Credit (L/C), Cash in Advance (CID), Cheque

- 200 Box Per Week

- 7 Days

- No

- Free samples available with shipping and taxes paid by the buyer

- BOX PACKING

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India

- ISO9001-2015

Product Description

GI Wire Buckle Long Product Description

A GI Wire Buckle (Galvanized Iron Wire Buckle) is a highly durable, corrosion-resistant fastening component designed specifically for strapping, packaging, and load securing applications. Manufactured from premium-quality galvanized iron wire, these buckles offer exceptional strength, stability, and resistance to rust and environmental wear, making them ideal for heavy-duty packaging solutions across various industries such as logistics, warehousing, construction, and export packaging.

The galvanization process involves coating the iron wire with a layer of zinc, which significantly enhances its resistance to moisture, oxidation, and corrosion. This ensures that GI wire buckles maintain their integrity and strength even in challenging outdoor or humid environments, extending the lifespan of the packaging system and safeguarding valuable goods during storage and transit.

One of the key advantages of GI wire buckles is their high tensile strength. They are engineered to withstand significant tension and pressure during the strapping process, preventing slippage or loosening of straps. This makes them a reliable choice for securing heavy loads, bundling products, and stabilizing cargo during transportation. Additionally, their reusable and cost-effective nature offers long-term value for businesses seeking sustainable packaging solutions.

GI wire buckles are widely compatible with various types of strapping materials, including cord strapping, PET strapping, and PP strapping, allowing for versatile usage across multiple sectors. The design of the buckle typically an open or closed loop configuration ensures a firm grip on the strap while enabling easy threading and tensioning without the need for complex tools. Their user-friendly design allows for quick application, reducing labor time and improving packaging efficiency.

In industrial and commercial operations, safety and reliability are paramount. GI wire buckles meet these requirements by delivering secure load containment and preventing accidental shifting or damage during handling and shipping. Whether used for palletizing goods, reinforcing cargo, or bundling construction materials, these buckles provide consistent performance and dependable results.

Furthermore, GI wire buckles are available in different sizes, thicknesses, and tensile strengths to match various load requirements, making them a versatile solution for both light and heavy-duty applications. Their combination of strength, durability, rust resistance, and cost efficiency has made them a trusted choice in the global packaging and logistics industry.

In summary, a GI Wire Buckle is more than just a small fastening accessory it is a crucial component in modern packaging systems. By ensuring secure strapping, enhancing load stability, and providing long-lasting performance, GI wire buckles help businesses protect their products, optimize their logistics operations, and maintain high standards of safety and reliability throughout the supply chain.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+