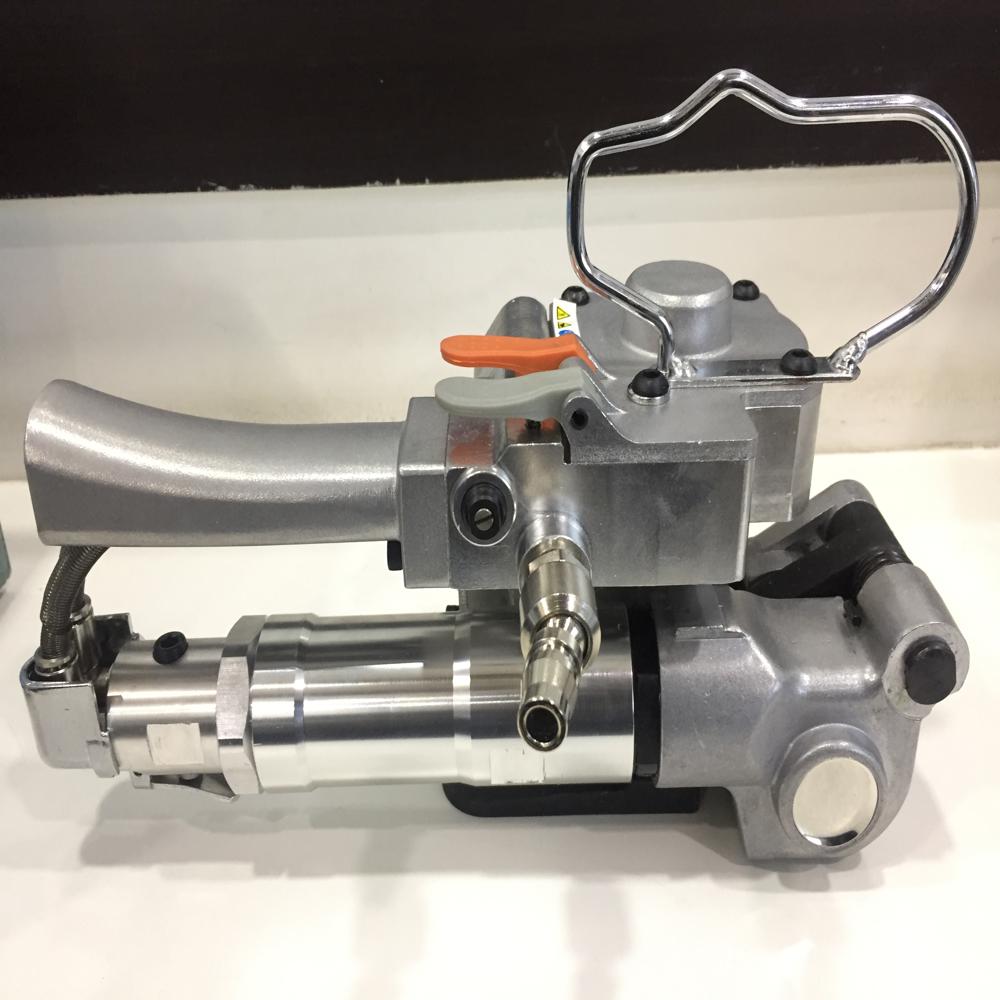

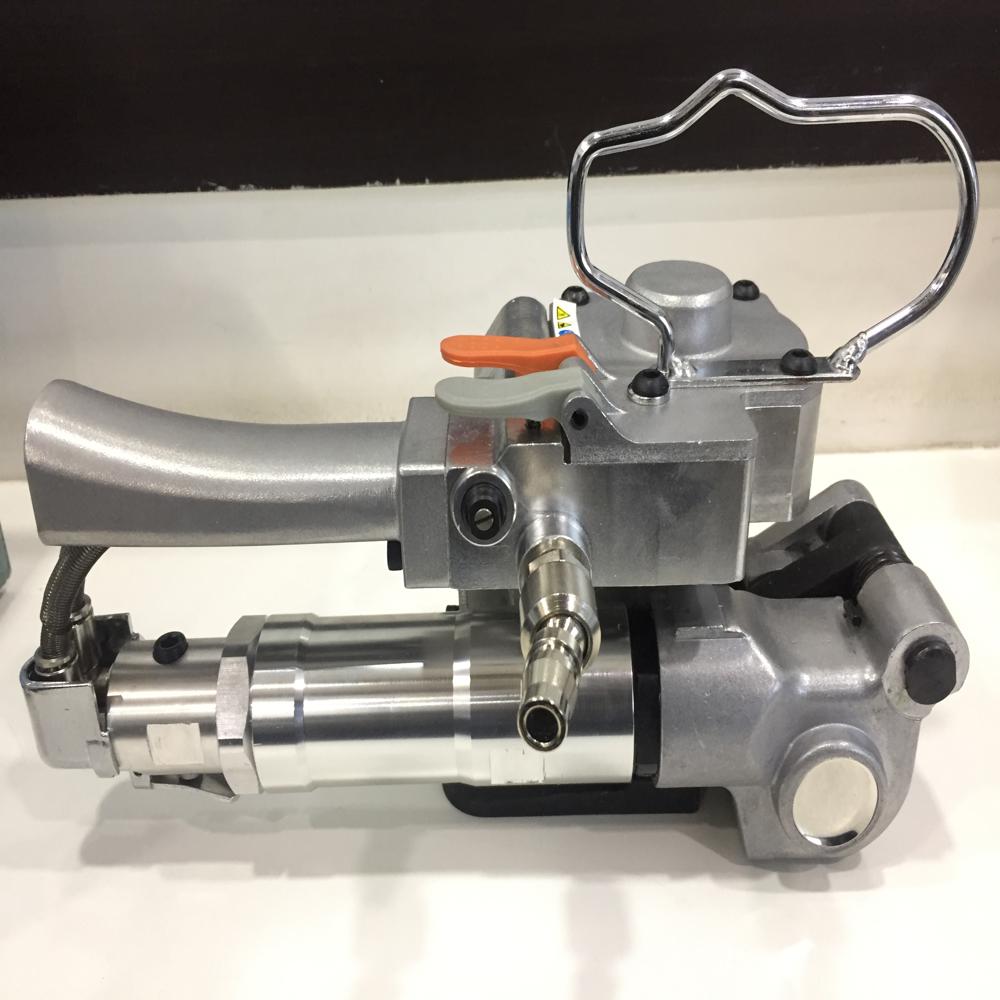

PET-PP Pneumatic Strapping tool

Product Details:

- Finish Type OTHER

- Coating Type ALLUMINIUM

- Color Silver

- Size 1

- Water Resistant YES

- Eco Friendly YES

- Usage & Applications PACKAGING

- Click to View more

PET-PP Pneumatic Strapping tool Price And Quantity

- 1 Piece

- 25000.0 INR/Piece

PET-PP Pneumatic Strapping tool Product Specifications

- 1

- 3 Inch (in)

- 1 Kilograms (kg)

- Silver

- ALLUMINIUM

- OTHER

- BOX PACKING

- Other

- BOX PACKING

- Steel

- 1 Kilograms (kg)

- 3 Inch

- PACKAGING

- YES

- YES

PET-PP Pneumatic Strapping tool Trade Information

- mundra

- Cash in Advance (CID), Cheque

- 10 Piece Per Week

- 7 Days

- No

- Contact us for information regarding our sample policy

- product packing

- Asia, Australia, Central America, North America, South America, Eastern Europe, Africa, Western Europe, Middle East

- All India

- ISO CERTIFICATE 2015

Product Description

What Are Pneumatic Tools?

Pneumatic (air-powered) tools are driven by compressed air from an air compressor, offering a high power-to-weight ratio, improved safety (no electric sparks), and cost-effectiveness. Commonly used across construction, automotive, manufacturing, and assembly industries, they operate via internal pneumatic motorseither linear or rotary

Key Specifications for Pneumatic Tools

1. Air Pressure (PSI/bar)

The force at which air is delivered. Common operating pressures range between 80120 PSI (5.58.3 bar) for many tools

2. Air Consumption (CFM or L/min)

Specifies how much air the tool uses to operate efficiently, typically in CFM (cubic feet per minute) or L/min. Determines compressor capacity needs

3. Free Speed (RPM)

Rotational speed when unloaded, usually listed in product tech specs. Important for tasks requiring high-speed operation

4. Torque (for impact wrenches)

Measured in ft-lbs or Nm. For instance, impact wrenches typically deliver 2001000 ft-lbs (2701356 Nm) at 90120 PSI

5. Weight and Size

Influences operator fatigue and tool handling:

-

Small wrenches weigh around 1.3 kg

-

models weigh about 45 lbs (1.82.3 kg)

-

Heavy-duty and 1 wrenches can weigh up to 11 lbs (5 kg)

6. Inlet Size & Thread Type

Ensure proper compatibility with hoses:

-

Common thread standards: NPT (America), PT (Asia), BSP (Europe)

-

Never mix thread types to avoid leakage

7. Hose Diameter

Manufacturers recommend appropriate hose sizes (in mm or inches) to ensure optimum performance

8. Noise Levels

Though not always listed, typical levels range from 70110 dB depending on the tool type

9. Durability

Often rated by expected cyclesimpact wrenches may last 10,000 to 50,000 cycles, while nail guns may endure 50,000 to 100,000 cycles

10. Certifications (India-specific)

In India, tools may carry the ISI mark under BIS certification (IS 5651:1987) to confirm steel quality and safety compliance

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+