Warehouse Bundling composite cord strap

Product Details:

- Load Capacity 360 Kilograms (kg)

- Usage & Applications pallatizing and bandling

- Thickness 1 Millimeter (mm)

- Water Resistant YES

- Print Type Flexo

- Finish Type plain

- Eco Friendly YES

- Click to View more

Warehouse Bundling composite cord strap Price And Quantity

- 2100.0 INR

- 20 Roll

Warehouse Bundling composite cord strap Product Specifications

- 1 Millimeter (mm)

- YES

- 360 Kilograms (kg)

- 20 Kilograms (kg)

- pallatizing and bandling

- plain

- Flexo

- 19 Millimeter (mm)

- Plastic

- YES

- pallatizing and bandling

- pallatizing and bandling

- 19mm

- white

Warehouse Bundling composite cord strap Trade Information

- mundra

- Cash in Advance (CID), Cheque, Letter of Credit (L/C)

- 500 Roll Per Week

- 7 Days

- No

- Within a certain price range free samples are available

- PALLATIZING AND BANDLING

- Asia, Australia, Central America, North America, South America, Eastern Europe, Middle East, Africa, Western Europe

- All India

- ISO9001-2015

Product Description

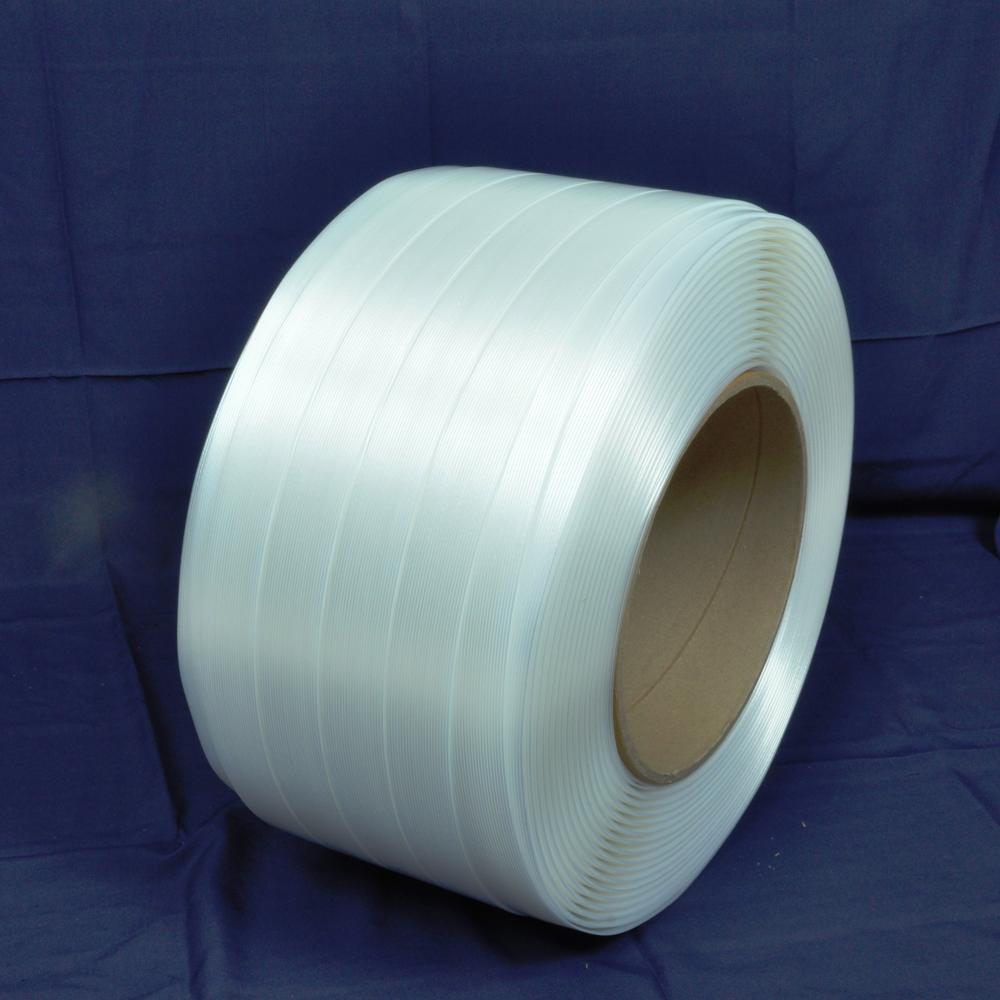

Composite Cord Strap The Modern Alternative to Steel Strapping

Composite Cord Strap, also known as Polyester Composite Strap or Synthetic Cord Strap, is a premium load-securing solution widely used across various industries for packaging, bundling, and cargo securing applications. Designed with high-tensile polyester fibers encapsulated within a durable polymer coating, this innovative strap delivers exceptional strength, flexibility, and resistance making it an ideal replacement for traditional steel strapping.

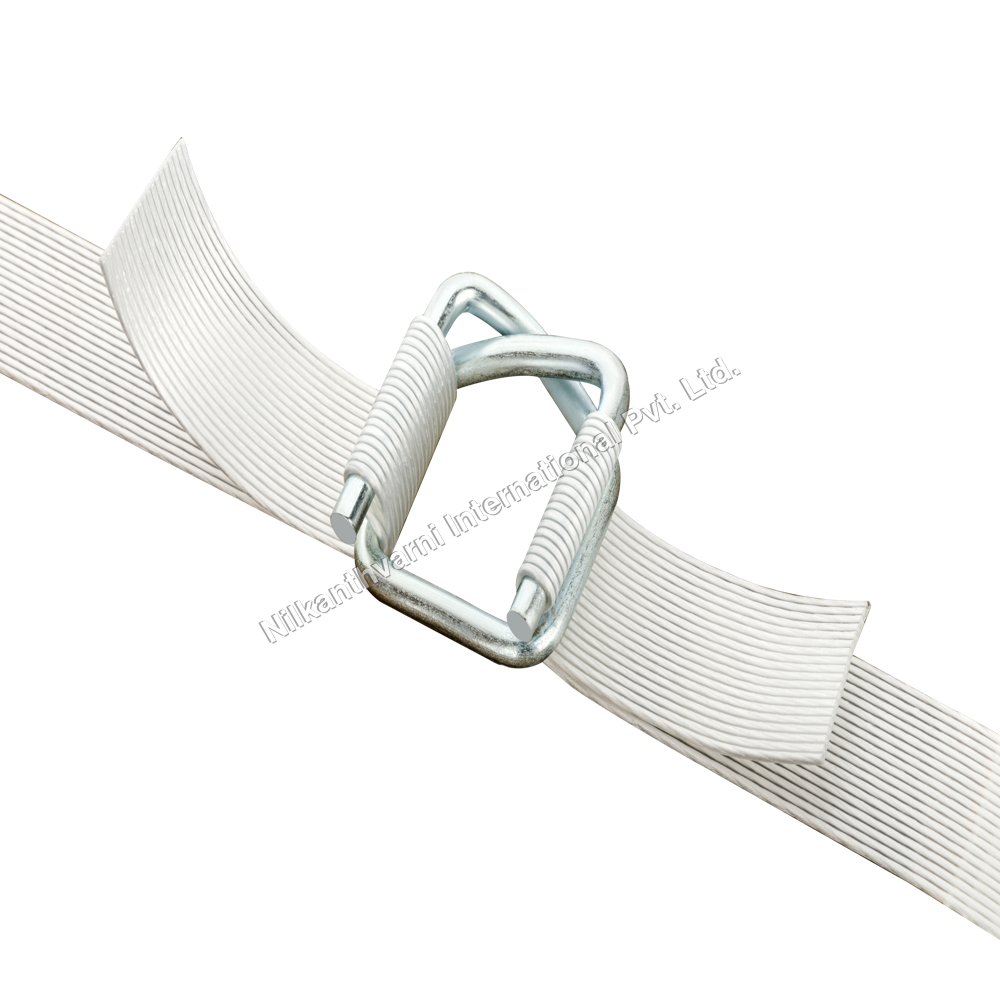

The composite cord strap is often referred to as the synthetic steel strap, because it provides the same or even greater holding power as steel, but with superior safety and handling benefits. Its unique composition ensures high breaking strength and consistent tension retention, offering a secure and reliable method for heavy-duty packaging and transportation of goods.

Composition and Design

Composite cord straps are manufactured from high-strength polyester yarns that form the core structure of the strap. These fibers are coated with a special polypropylene (PP) or polymer layer, which enhances abrasion resistance and protects the strap from damage due to rough surfaces or environmental exposure. This combination of materials results in a strap that is lightweight, flexible, and weatherproof, yet capable of securing loads weighing several tons.

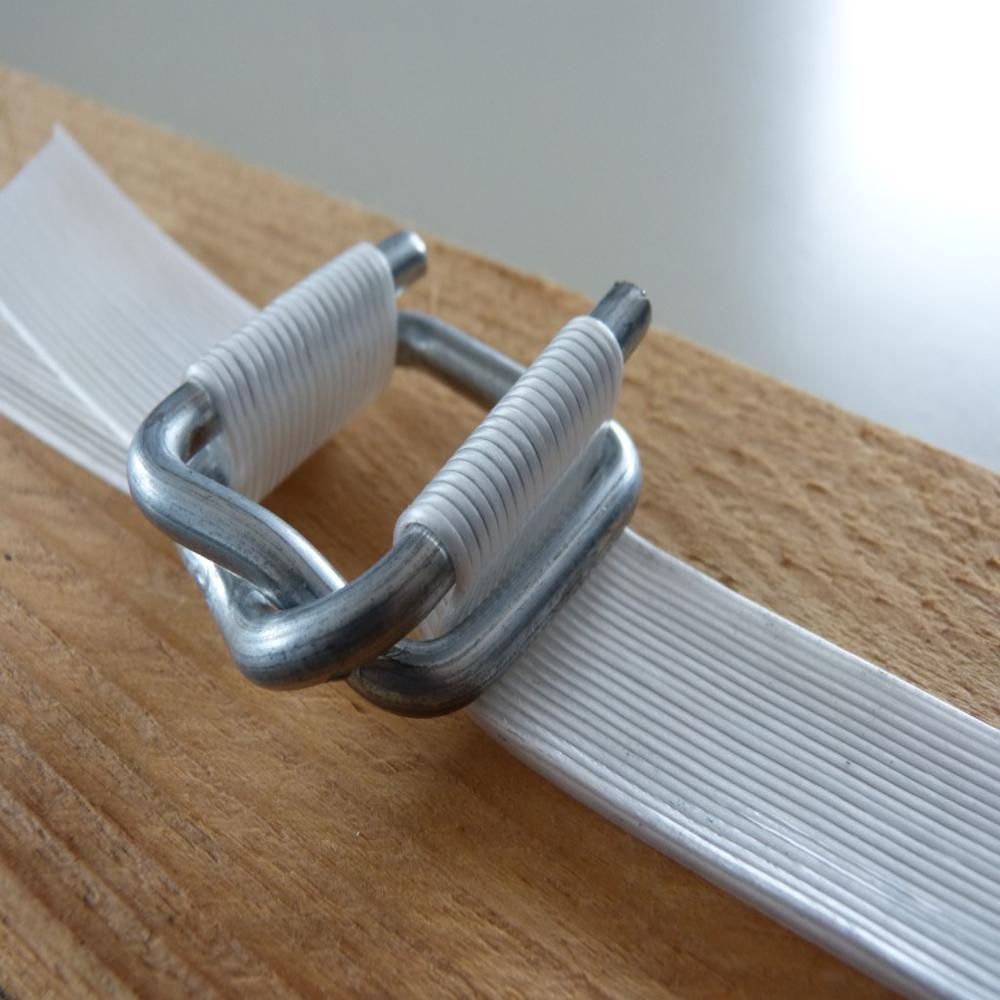

The straps smooth surface prevents scratching or damaging of packaged goods, while its ability to maintain tension ensures stability even during long-distance or overseas transportation.

Strength, Durability, and Performance

Composite cord strapping offers exceptional tensile strength, making it suitable for heavy-duty industrial applications. It has a high retained tension, meaning it continues to hold loads tightly even when subjected to vibrations, shocks, or changes in temperature and humidity.

Unlike steel straps, composite straps do not rust, corrode, or stain the cargo. They also resist UV radiation and moisture, making them perfect for outdoor and export packaging. The internal polyester fibers give the strap flexibility and shock absorption capacity, ensuring the protection of fragile or irregularly shaped items during handling and transit.

Safety and Ease of Use

Safety is a major advantage of composite cord strap. Since it does not have sharp edges, it eliminates the risk of injuries commonly associated with steel strapping. It does not spring back dangerously when cut, and workers can handle it comfortably without protective gloves.

Composite cord straps are also lightweight and easy to handle, reducing operator fatigue and improving packing efficiency. They can be applied using manual or pneumatic tensioning tools and secured with phosphate-coated steel buckles for maximum grip and tension retention. The process requires no sealing machines or welding, which makes it cost-effective and simple to operate in any environment.

Applications

Composite cord straps are versatile and suitable for multiple sectors and purposes, including:

-

Logistics and Transportation: Securing cargo during transit on trucks, containers, and ships.

-

Construction Industry: Bundling pipes, timber, tiles, and heavy materials.

-

Metal and Steel Industry: Strapping metal coils, bars, and sheets without damaging surfaces.

-

Automotive Industry: Securing machinery, parts, and vehicle components.

-

Wood and Furniture Industry: Packing wooden pallets, furniture, and boards for export.

-

Warehousing and Export Packaging: Palletizing goods for long-distance or international shipments.

Its ability to maintain high tension and adapt to load movements makes it a preferred choice for exporters and logistics providers across the world.

Eco-Friendly and Cost-Effective Solution

In addition to its superior performance, composite cord strap is an environmentally friendly packaging solution. Made from recyclable polyester, it supports sustainable packaging practices and reduces environmental impact compared to steel strapping.

It is also a cost-effective alternative since it requires no special tools, corrosion protection, or maintenance. The lightweight design reduces shipping costs, and its reusability in some cases further enhances cost savings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+