GST No- 24AAJCN5231A1ZZ

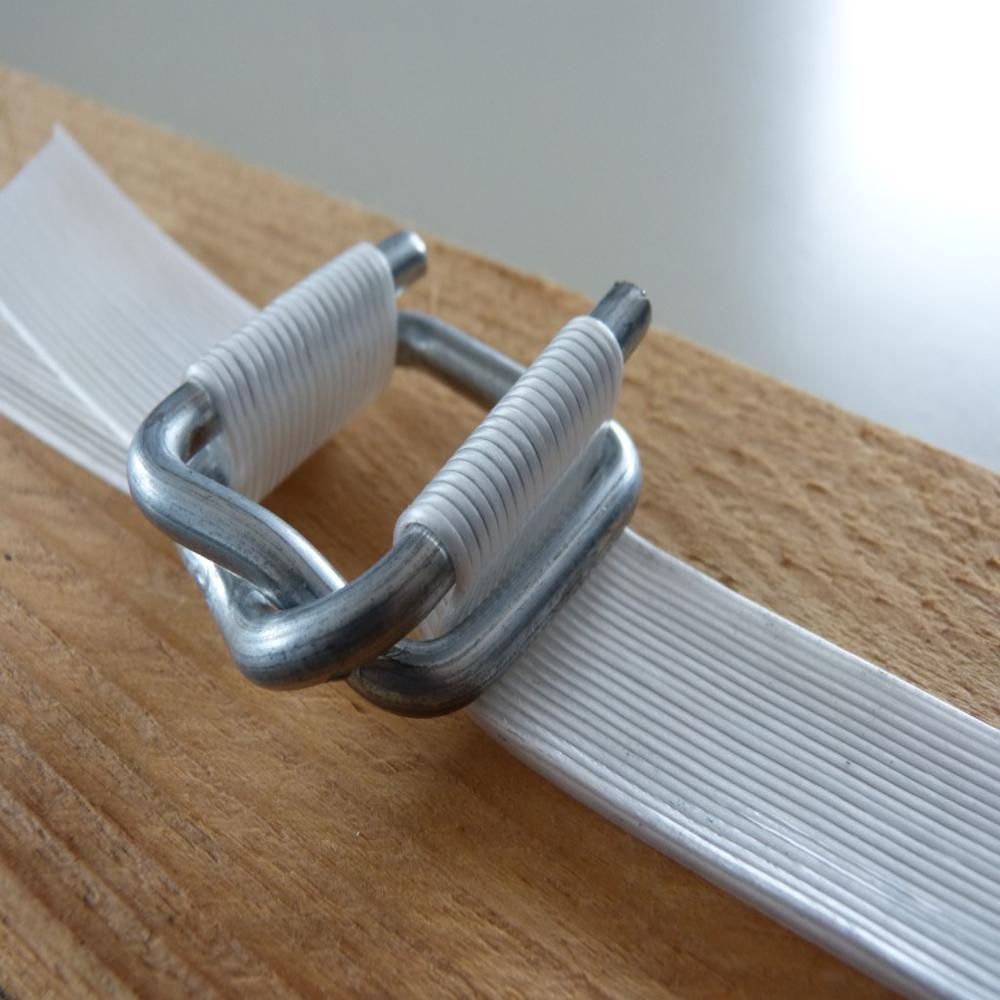

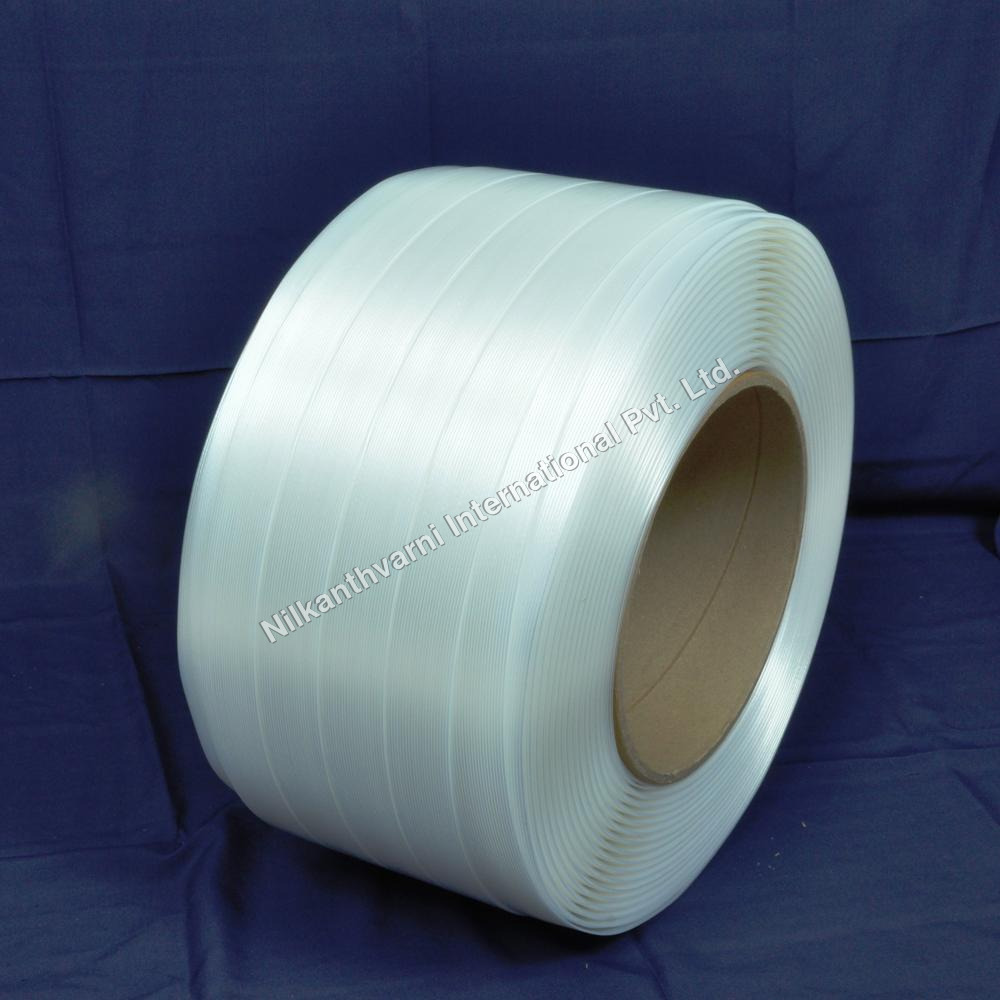

TRANSPHARENT COMPOSITE CORD STRAP

2100.0 INR/Roll

Product Details:

- Print Type Flexo

- Size 19

- Thickness 1 Millimeter (mm)

- Eco Friendly YES

- Material Plastic

- Usage & Applications PALLETIZING AND BUNDLING

- Color WHITE

- Click to View more

X

TRANSPHARENT COMPOSITE CORD STRAP Price And Quantity

- 20 Roll

- 2100.0 INR/Roll

TRANSPHARENT COMPOSITE CORD STRAP Product Specifications

- 1 Millimeter (mm)

- 19 Millimeter (mm)

- YES

- 360 Kilograms (kg)

- YES

- Plastic

- PALLETIZING AND BUNDLING

- PLAIN

- PALLETIZING AND BUNDLING

- Flexo

- PALLETIZING AND BUNDLING

- WHITE

- 19

- 20 Kilograms (kg)

TRANSPHARENT COMPOSITE CORD STRAP Trade Information

- MUNDRA

- Cash in Advance (CID), Cheque, Letter of Credit at Sight (Sight L/C)

- 300 Roll Per Week

- 7 Days

- Yes

- Within a certain price range free samples are available

- BOX PACKING

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India

- ISO9001-2015 DNV-GL

Product Description

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email