GST No- 24AAJCN5231A1ZZ

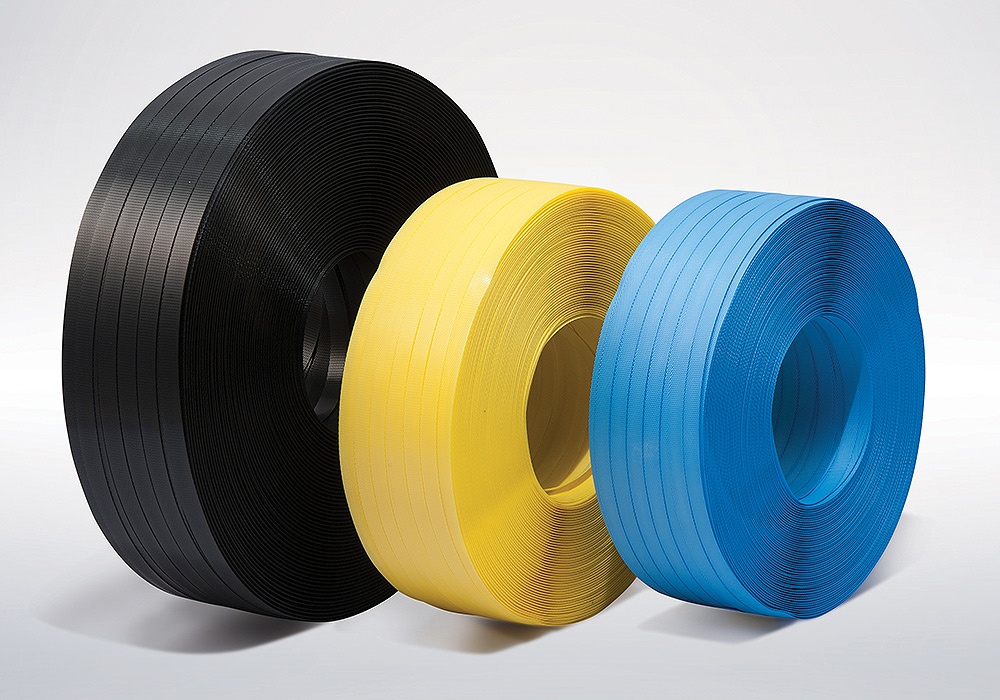

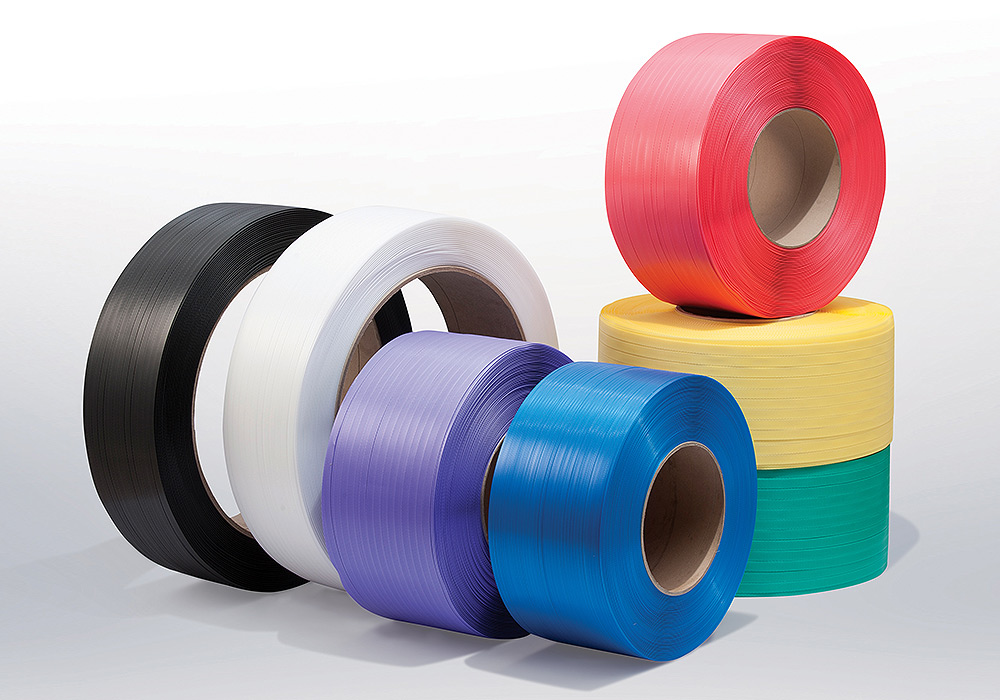

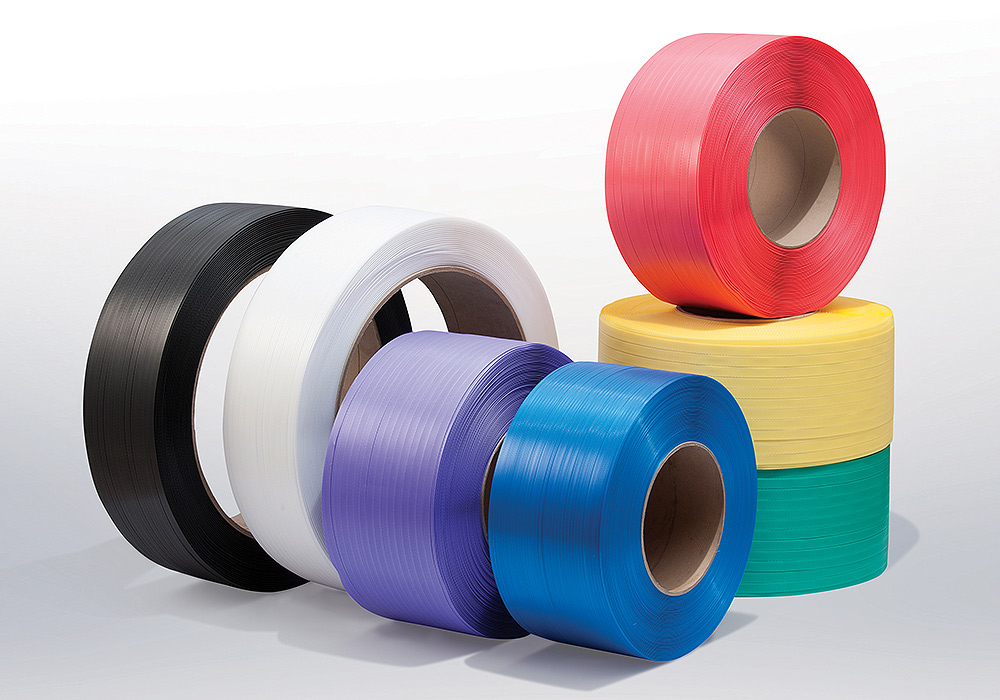

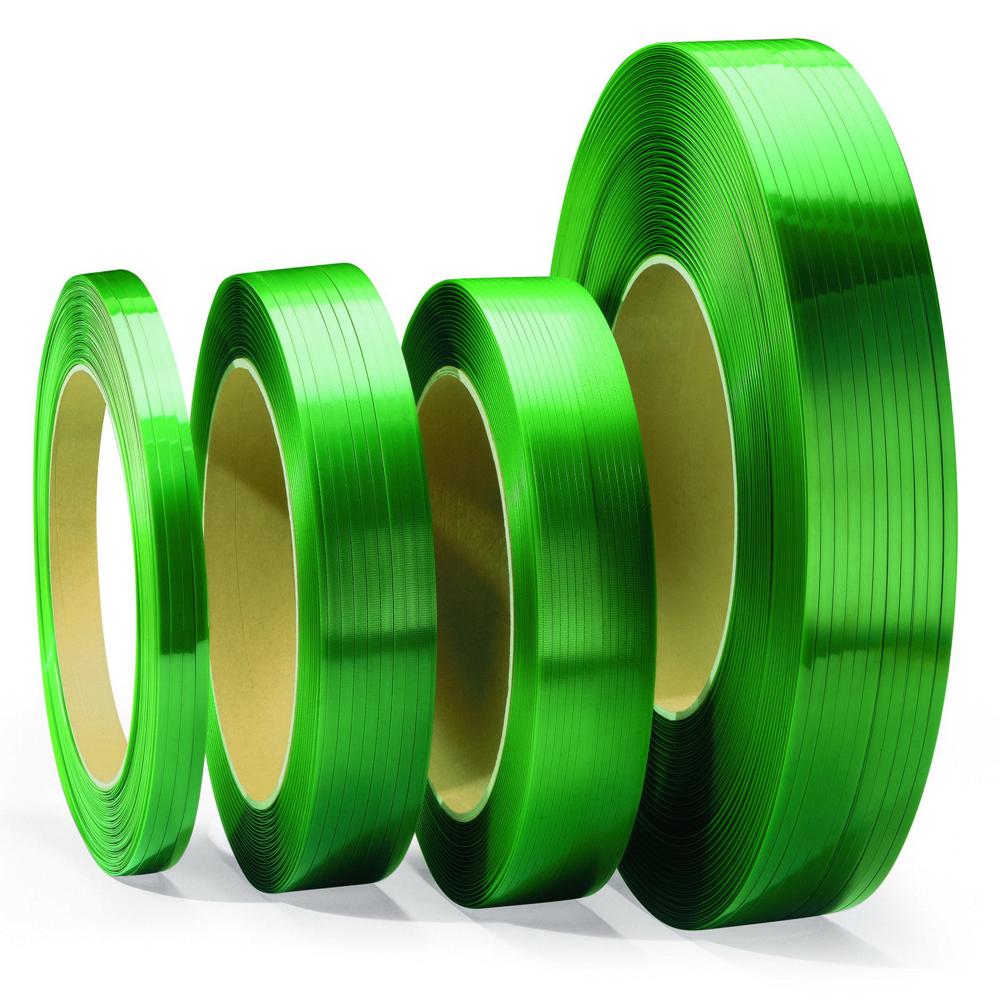

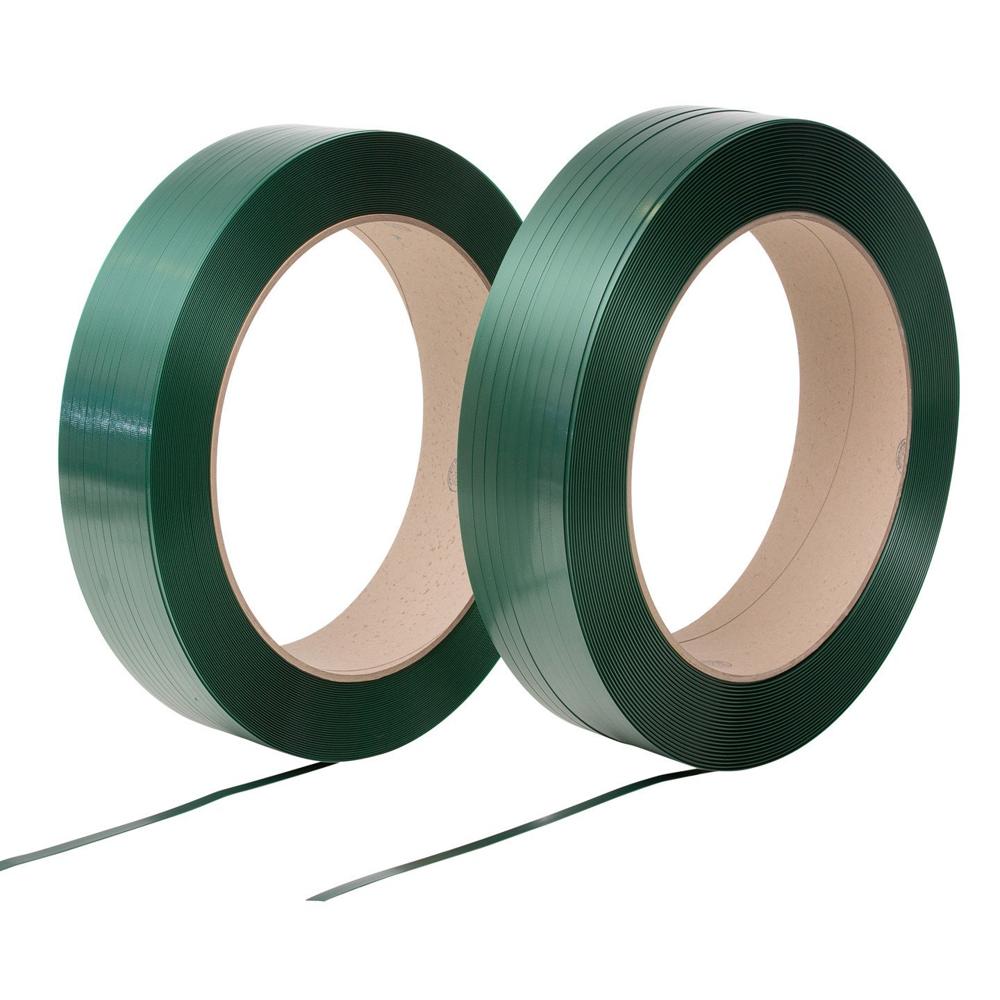

transparent pp strapping roll

1600.0 INR/Roll

Product Details:

- Print Type Flexo

- Thickness 0.6 Millimeter (mm)

- Finish Type embossed

- Size 15mm

- Water Resistant YES

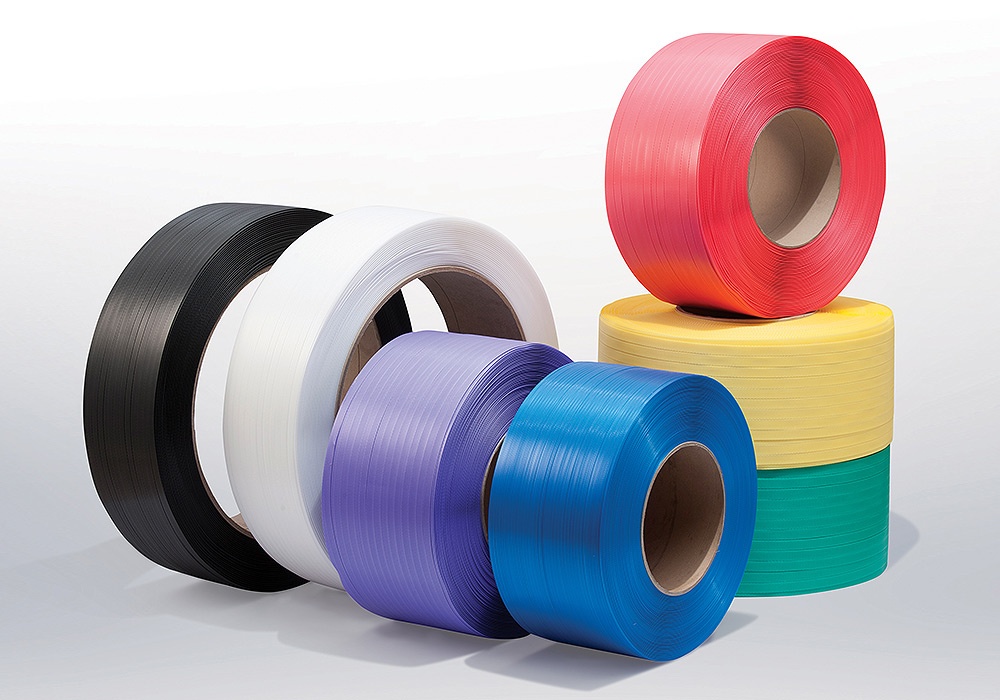

- Color customize

- Usage & Applications box packing

- Click to View more

X

transparent pp strapping roll Price And Quantity

- 100 Roll

- 1600.0 INR/Roll

transparent pp strapping roll Product Specifications

- Plastic

- YES

- box packing

- box packing

- YES

- customize

- 15mm

- embossed

- box packing

- 0.6 Millimeter (mm)

- 15 Millimeter (mm)

- 8 Kilograms (kg)

- Flexo

transparent pp strapping roll Trade Information

- mundra

- Cash in Advance (CID), Cheque, Letter of Credit at Sight (Sight L/C)

- 500 Roll Per Week

- 7 Days

- Yes

- Within a certain price range free samples are available

- BOX PACKING

- South America, Eastern Europe, Western Europe, Asia, Australia, Central America, North America, Middle East, Africa

- All India

- ISO9001-2015 DNV-GL

Product Description

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email