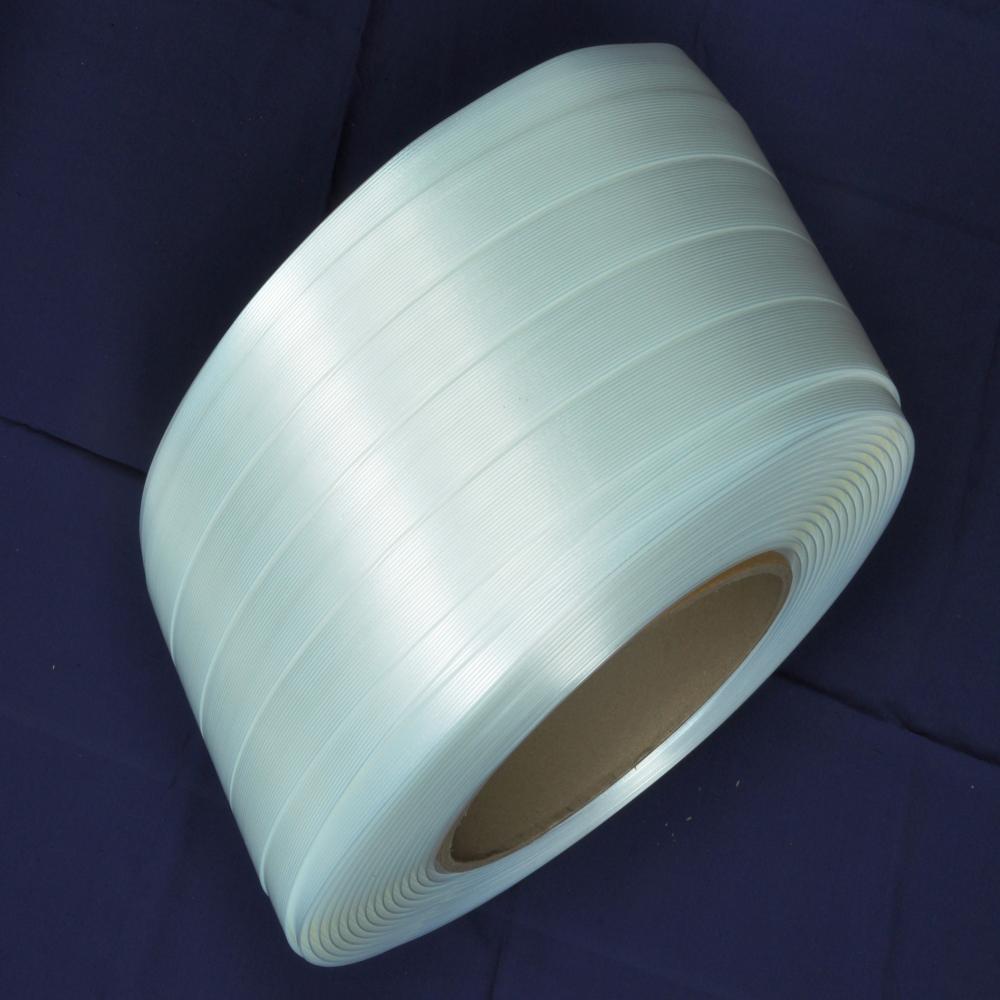

polyester composite strapping wholesale

Product Details:

- Thickness 1 Millimeter (mm)

- Color WHITE

- Print Type Flexo

- Usage & Applications PALLATIZING AND BANDLING

- Load Capacity 730 Kilograms (kg)

- Finish Type PLAIN

- Eco Friendly YES

- Click to View more

polyester composite strapping wholesale Price And Quantity

- 20 Roll

- 2100.0 INR/Roll

polyester composite strapping wholesale Product Specifications

- 25MM

- YES

- 20 Kilograms (kg)

- Plastic

- PALLATIZING AND BANDLING

- YES

- PLAIN

- PALLATIZING AND BANDLING

- 25 Millimeter (mm)

- 730 Kilograms (kg)

- PALLATIZING AND BANDLING

- Flexo

- WHITE

- 1 Millimeter (mm)

polyester composite strapping wholesale Trade Information

- MUNDRA

- Cheque, Cash in Advance (CID), Letter of Credit (L/C)

- 500 Roll Per Week

- 7 Days

- No

- Within a certain price range free samples are available

- PALLATIZING AND BANDLING

- North America, Western Europe, Middle East, Asia, Australia, Central America, South America, Eastern Europe, Africa

- All India

- ISO9001-2015 DNV-GL

Product Description

Composite Cord Strap Full Long Description with All Technical Details

Composite Cord Strap, also known as Polyester Composite Strapping, is a high-strength, non-metallic load securing solution designed for heavy-duty packaging, palletizing, and cargo lashing applications. Made from high-tenacity polyester fibers coated with a robust polymer, this strapping delivers exceptional tensile strength, shock absorption, and resistance to harsh environmental conditions. It is widely used as a safer alternative to steel strapping due to its superior handling safety, corrosion resistance, and ability to protect goods from damage.

Engineered for demanding industrial packaging needs, composite cord strap ensures secure load stability for domestic transport, export shipments, and containerized cargo. The strap maintains consistent performance across extreme temperatures, moisture, and heavy vibration, making it ideal for industries such as logistics, shipping, timber, glass, steel, automotive, manufacturing, construction, chemical, and warehousing.

Material Structure & Manufacturing

Composite cord strap is manufactured using:

-

High-tenacity polyester yarns arranged in parallel to maximize linear strength.

-

Polypropylene (PP) polymer coating that binds and protects the internal fibers.

-

Advanced heat-bonding technology to create strong, flexible, and durable strapping.

This construction provides high tensile strength, no sharp edges, and excellent elongation, allowing the strap to absorb shock during transportation.

Key Features

-

High Tensile Strength: Suitable for medium to extremely heavy loads.

-

Shock Absorption: Maintains tension and absorbs movement during transit.

-

Rust & Weather Resistant: Unlike steel strapping, composite strap never rusts or stains the product.

-

Safe to Handle: No sharp edgesprevents injuries to workers during application.

-

Lightweight & Flexible: Easy to apply, reposition, or cut without special safety gear.

-

Non-abrasive Surface: Prevents damage to products, coatings, or packaging material.

-

UV & Moisture Resistant: Performs reliably in outdoor and maritime environments.

-

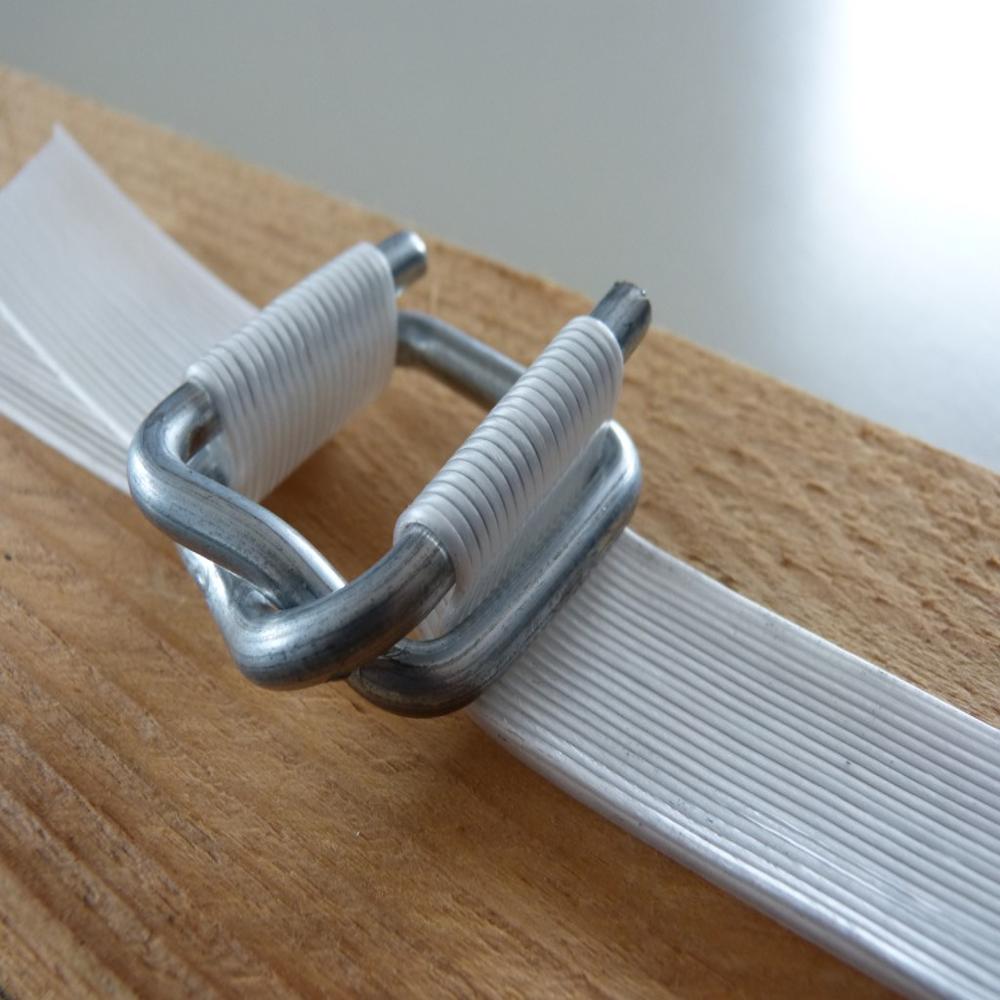

Reusable with Buckles: Combined with galvanized/phosphated buckles for maximum locking efficiency.

Advantages of Composite Cord Strap

1. Stronger Than Woven Polyester Strap

Composite straps bonded coating provides higher rigidity and strength, making it ideal for heavy-duty lashing.

2. Safer Replacement for Steel Strapping

-

No recoil effect

-

No sharp edges

-

No risk of injury during cutting

-

No corrosion or staining on products

3. Excellent Load Stability

The strap grips tightly around irregular shapes, pallets, crates, pipes, and machinery, ensuring secure transportation.

4. Resistant to Weather & Chemicals

Perfect for export shipments, outdoor storage, and marine environments.

5. Cost-Effective & Economical

Provides similar holding ability to steel straps but at lower cost with increased safety and ease of use.

Available Sizes & Technical Specifications

(Common market standards)

| Width (mm) | Breaking Strength | System Strength | Core Size | Roll Length |

|---|---|---|---|---|

| 13 mm | 300400 kg | 550700 kg | 200/406 mm | 11001500 m |

| 16 mm | 450600 kg | 9001200 kg | 200/406 mm | 8501100 m |

| 19 mm | 600800 kg | 13001600 kg | 200/406 mm | 600800 m |

| 25 mm | 10001200 kg | 20002500 kg | 200/406 mm | 400600 m |

| 32 mm | 15002000 kg | 30004500 kg | 200/406 mm | 250500 m |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+