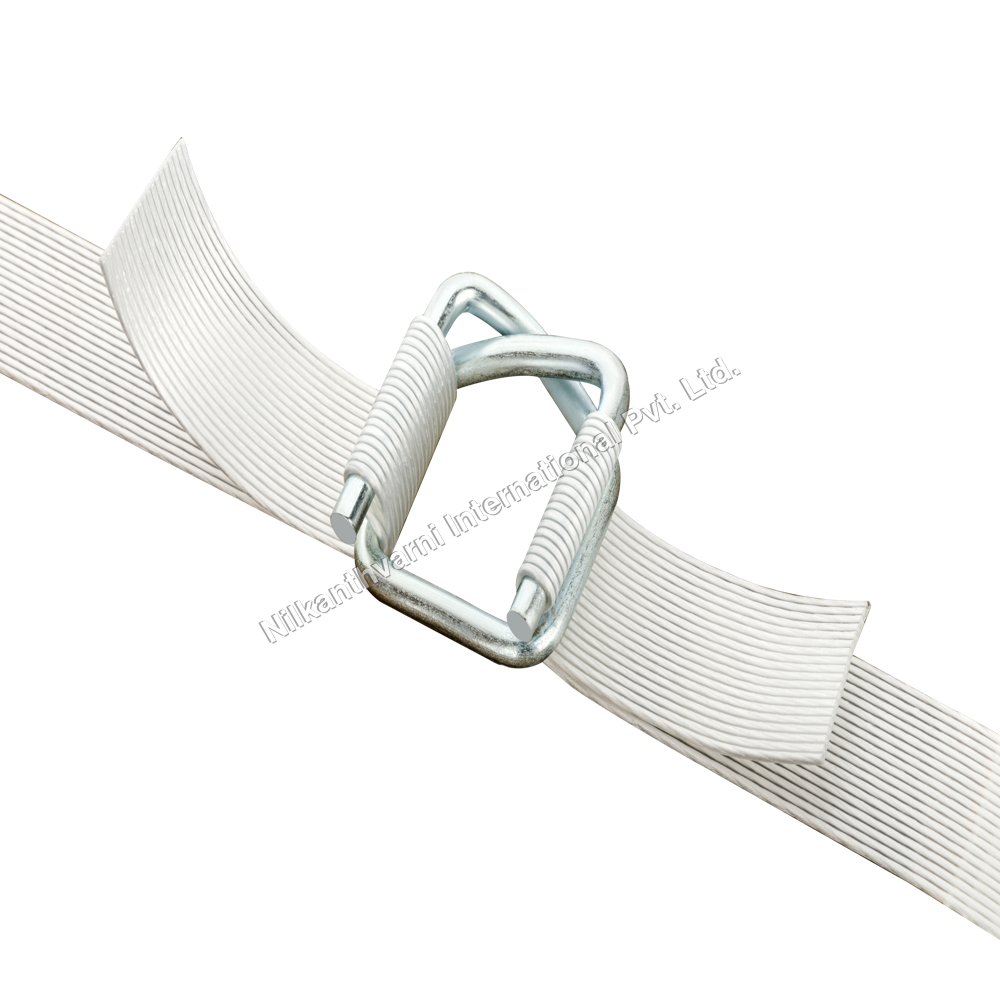

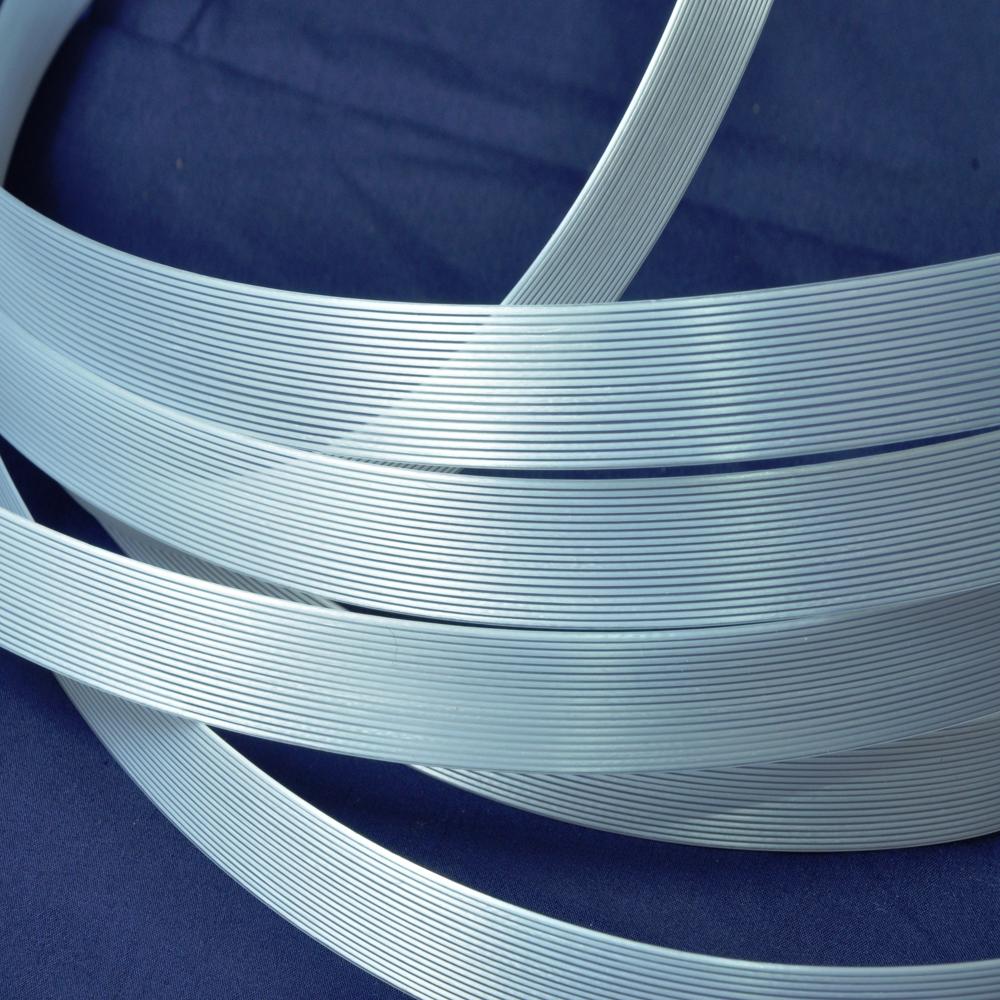

HIGH ELASTIC AND FELXIBLE CORD STRAP

Product Details:

- Water Resistant YES

- Size 19MM

- Color WHITE

- Thickness 1 Millimeter (mm)

- Material Plastic

- Finish Type PLAIN

- Load Capacity 360 Kilograms (kg)

- Click to View more

HIGH ELASTIC AND FELXIBLE CORD STRAP Price And Quantity

- 1100.0 INR/Roll

- 20 Roll

HIGH ELASTIC AND FELXIBLE CORD STRAP Product Specifications

- YES

- PALLATIZING AND BANDLING

- PALLATIZING AND BANDLING

- Flexo

- 19 Millimeter (mm)

- 20 Kilograms (kg)

- PLAIN

- 360 Kilograms (kg)

- 1 Millimeter (mm)

- Plastic

- PALLATIZING AND BANDLING

- WHITE

- 19MM

- YES

HIGH ELASTIC AND FELXIBLE CORD STRAP Trade Information

- MUNDRA

- Cash in Advance (CID), Cheque, Letter of Credit (L/C)

- 500 Roll Per Week

- 7 Days

- No

- Within a certain price range free samples are available

- PALLATIZING AND BANDLING

- South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia, Australia, North America

- All India

- ISO9001-2015

Product Description

Cord Strap Long Description

Cord Strap, also known as Polyester Cord Strapping or Composite Cord Strap, is a high-strength, non-metallic strapping material designed to secure heavy loads and provide maximum load stability during transportation and storage. It is manufactured from high-tenacity polyester yarns that are either woven, bonded, or coated with a polymer layer to create a durable, flexible, and weather-resistant packaging solution.

Cord strap is widely recognized as a safer and more efficient alternative to steel strapping, offering comparable tensile strength while being lighter, rust-free, and easy to handle. It is primarily used for industrial packaging, export cargo, container lashing, palletizing, and heavy-duty load securing.

Material and Structure

Cord straps are made from high-quality polyester fibers that provide superior strength, elongation, and resistance to impact. These fibers are either:

-

Woven (Woven Cord Strap) providing maximum flexibility and high shock absorption.

-

Composite (Coated Cord Strap) featuring a polymer coating that enhances abrasion resistance and makes it easy to feed under pallets and through buckles.

The polyester material ensures that the strap maintains tension even during long storage or extreme temperature changes. Unlike steel straps, it does not rust or damage product surfaces, making it suitable for sensitive or delicate cargo such as painted machinery, wood products, or chemical containers.

Performance and Strength

Cord straps are known for their high tensile strength and excellent shock absorption. Depending on the type and size, cord straps can withstand loads ranging from 300 kg to over 2,000 kg, making them suitable for securing large and heavy loads on containers, flatbeds, rail cars, and ships.

Key performance features include:

-

High Retained Tension maintains load stability even under vibration or shifting.

-

Shock Absorption absorbs impacts without breaking.

-

Non-Corrosive and Weather Resistant performs well in humid, wet, or salty conditions.

-

Flexible and Safe easy to handle without sharp edges or risk of injury.

-

Reusable and Recyclable supports sustainable packaging.

Types of Cord Strap

-

Woven Cord Strap:

Made from woven polyester fibers, this strap is flexible, tear-resistant, and used for medium to heavy loads. It can be re-tensioned and reused multiple times. -

Composite Cord Strap:

Coated with a polypropylene layer, composite strap offers excellent abrasion resistance and rigidity, making it ideal for threading through pallets or metal surfaces. -

Hot Melt Cord Strap:

Manufactured using adhesive bonding technology, hot melt straps provide smooth edges and high strength, commonly used in medium-duty load securing.

Applications

Cord straps are used across various industries for cargo securing, bundling, and lashing. Their versatility makes them the preferred choice in:

-

Shipping and Export Packaging

-

Container Lashing and Palletizing

-

Logistics and Transportation

-

Automotive and Machinery Packaging

-

Wood, Timber, and Lumber Bundling

-

Steel and Metal Product Packaging

-

Brick, Tile, and Construction Material Packing

-

Paper, Textile, and Fiber Industry

Cord straps are often paired with phosphate-coated buckles, tensioners, and dispensers to ensure a reliable and secure load. The combination of strap and buckle provides a high joint efficiency, allowing re-tensioning even after long-distance transit.

Advantages of Cord Strap

-

High Strength and Reliability: Provides superior load security and tension retention.

-

Safe Handling: No sharp edges; eliminates risk of injury compared to steel strapping.

-

Rust and Corrosion-Free: Suitable for outdoor and marine transport.

-

Lightweight and Flexible: Easy to handle, carry, and apply.

-

Reusable and Recyclable: Environmentally friendly alternative to metal straps.

-

Non-Damaging: Does not scratch, dent, or rust surfaces of packed goods.

-

UV and Weather Resistant: Performs under extreme conditions.

-

Shock Absorbing: Ideal for fragile and vibration-sensitive goods.

-

Cost-Effective: Reduces overall packaging and labor costs.

-

Customizable: Available in different widths, strengths, and colors.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+