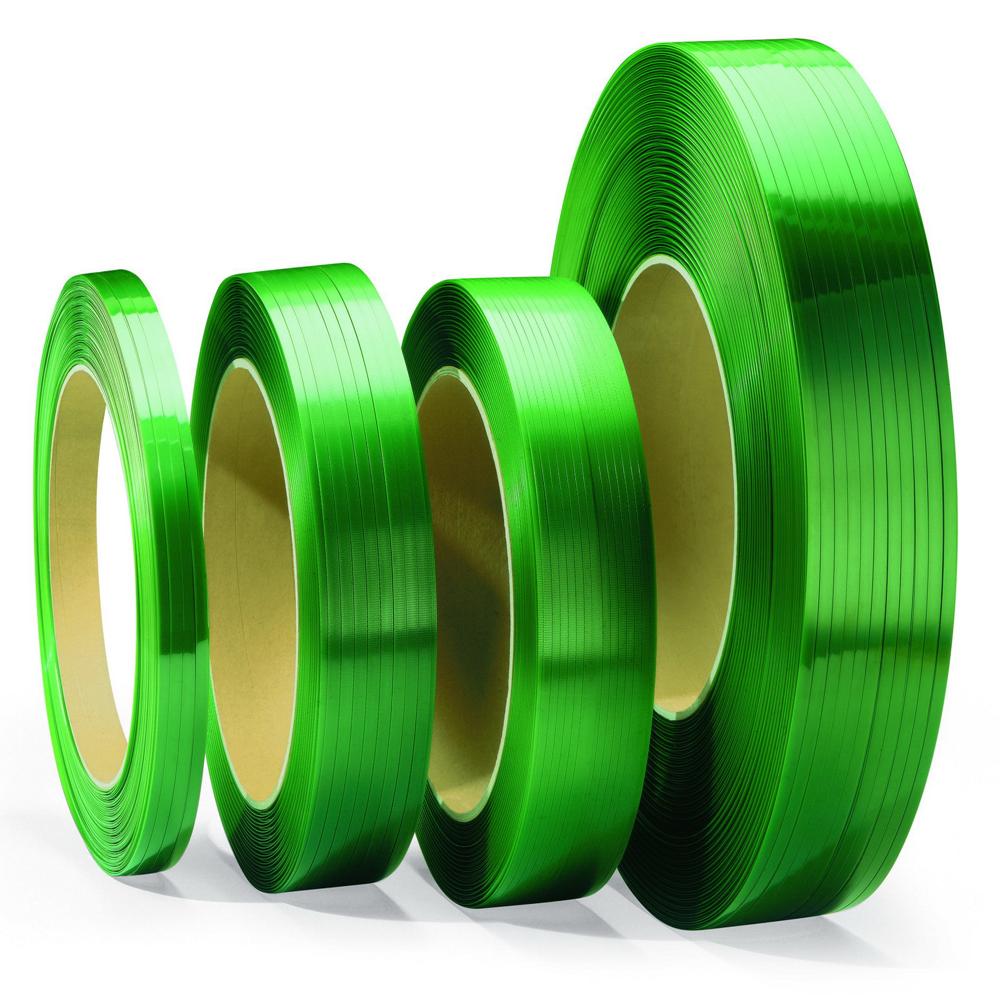

Friction weld pet strap

Product Details:

- Print Type Flexo

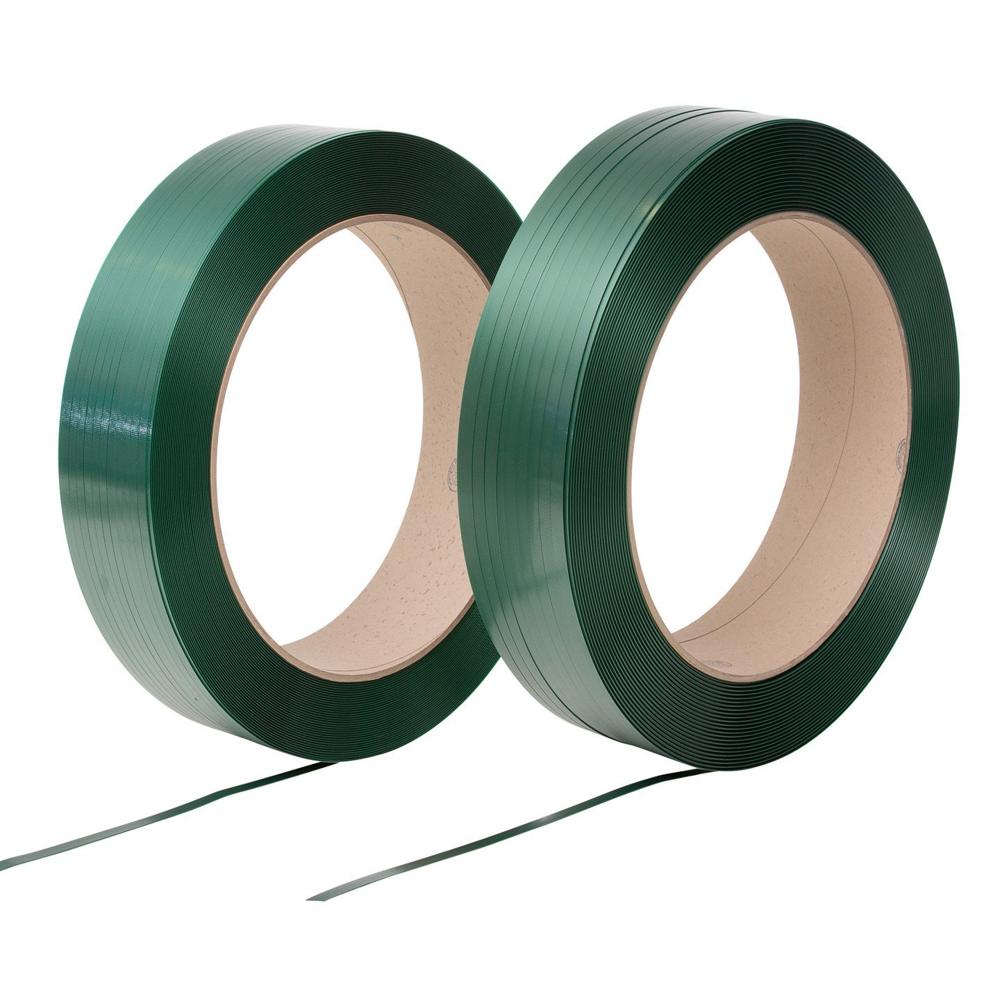

- Color green

- Size 12mm

- Load Capacity 290 Kilograms (kg)

- Material Plastic

- Water Resistant YES

- Thickness 0.7 Millimeter (mm)

- Click to View more

Friction weld pet strap Price And Quantity

- 10 Roll

- 1600.0 INR/Roll

Friction weld pet strap Product Specifications

- pallatizing and bandlling

- plain

- 12 Millimeter (mm)

- 0.7 Millimeter (mm)

- pallatizing and bandlling

- YES

- 290 Kilograms (kg)

- green

- Flexo

- 12mm

- YES

- Plastic

- 20 Kilograms (kg)

- pallatizing and bandlling

Friction weld pet strap Trade Information

- mundra

- Cash in Advance (CID), Cheque, Letter of Credit (L/C)

- 500 Roll Per Week

- 7 Days

- No

- Free samples are available

- PALLATIZING AND BANDLLING

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India

- ISO9001-2015 DNV-GL

Product Description

Long Description

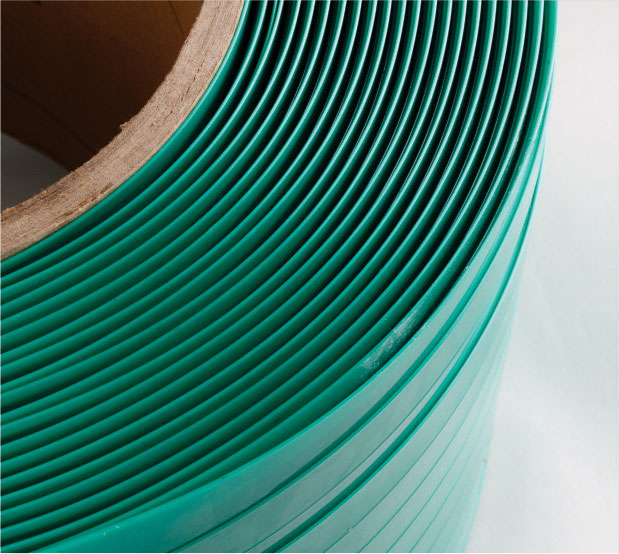

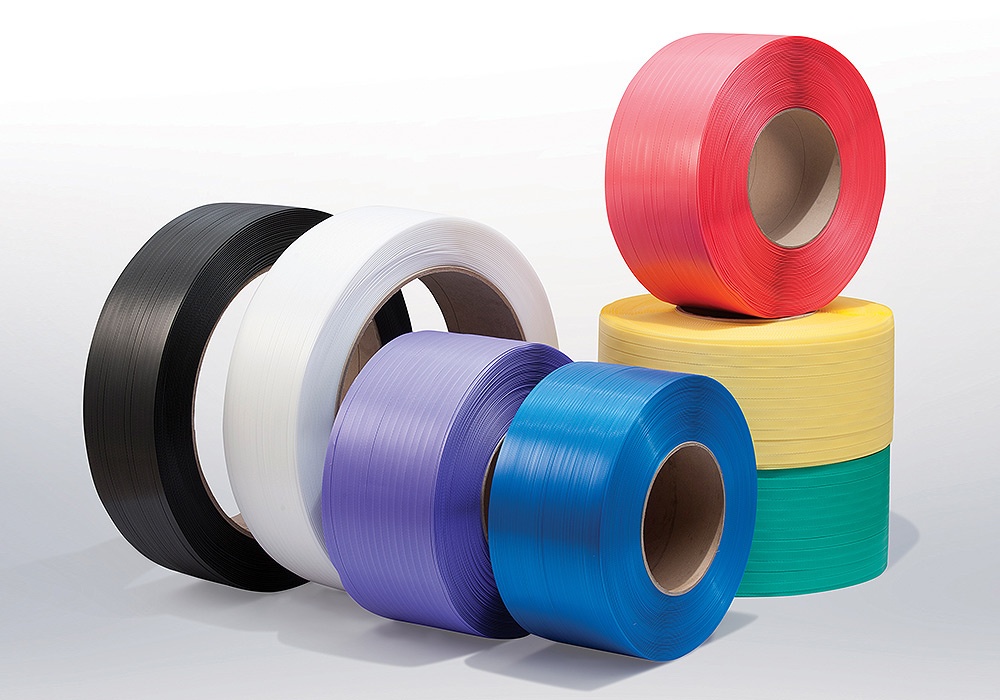

PET Strap, also known as Polyester Strapping, is a high-performance packaging and load-securing solution widely used in various industries for bundling, palletizing, and securing heavy loads during storage and transportation. Made from polyethylene terephthalate (PET), a type of strong, durable, and lightweight thermoplastic polymer, PET strapping is designed to provide exceptional tensile strength, elongation, and resistance to environmental factors. It has become the preferred alternative to traditional steel and polypropylene (PP) strapping due to its superior strength-to-weight ratio, cost-effectiveness, and ease of handling.

One of the most significant advantages of PET strapping is its high tensile strength, which makes it ideal for securing heavy loads such as bricks, steel coils, timber, glass, tiles, cartons, and palletized goods. Despite being lightweight and flexible, PET strap can withstand high tension without breaking, offering consistent and reliable load stability throughout the supply chain. Its shock-absorption capability also helps protect products from sudden impacts and vibrations during transportation, reducing the risk of damage.

In addition to strength, PET strap exhibits excellent elongation and recovery properties. It can stretch under tension and return to its original shape, maintaining a tight hold on the package even if the load shifts or settles. Unlike steel straps, PET strapping does not rust, corrode, or leave stains on the packaged goods, making it ideal for industries such as food and beverage, pharmaceuticals, logistics, construction, metalworking, and manufacturing.

PET straps are also known for their resistance to ultraviolet (UV) radiation and temperature fluctuations, allowing them to be used for long-term outdoor storage without losing performance. They are compatible with both manual strapping tools and fully automatic strapping machines, providing flexibility for small-scale packaging operations as well as high-speed industrial production lines.

From a sustainability perspective, PET straps are 100% recyclable and often manufactured from recycled PET materials (such as used plastic bottles), contributing to a circular economy and reducing environmental impact. Their lighter weight compared to steel strapping also reduces shipping costs and carbon emissions, making them an eco-friendly and cost-efficient choice for modern packaging solutions.

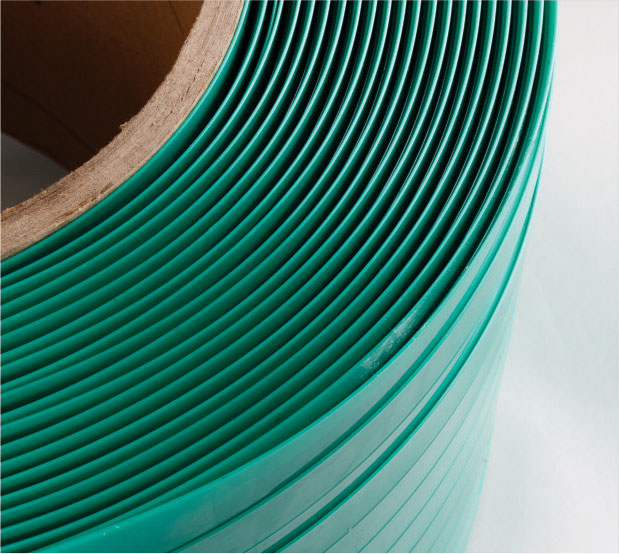

With their smooth or embossed surface finish, uniform width and thickness, and excellent joint efficiency when sealed with friction welding, PET straps ensure reliable performance and secure bundling for a wide range of applications. They are available in various widths (typically 9 mm to 32 mm), thicknesses, tensile strengths, and colors to meet specific packaging requirements.

Key Features and Benefits of PET Strap

-

High Tensile Strength: Provides strong and secure load containment for heavy-duty applications.

-

Excellent Elongation & Recovery: Absorbs shocks and maintains tension over time.

-

Rust-Free & Corrosion-Resistant: Safe for sensitive goods and long-term storage.

-

UV & Weather Resistant: Suitable for outdoor storage and harsh environments.

-

Lightweight & Safe to Handle: Easier and safer than steel strapping.

-

Recyclable & Eco-Friendly: Contributes to sustainable packaging solutions.

-

Cost-Effective: Lower material, handling, and shipping costs compared to steel.

-

Machine & Manual Compatible: Works with various strapping tools and systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+