Corrugated Box Strap

Product Details:

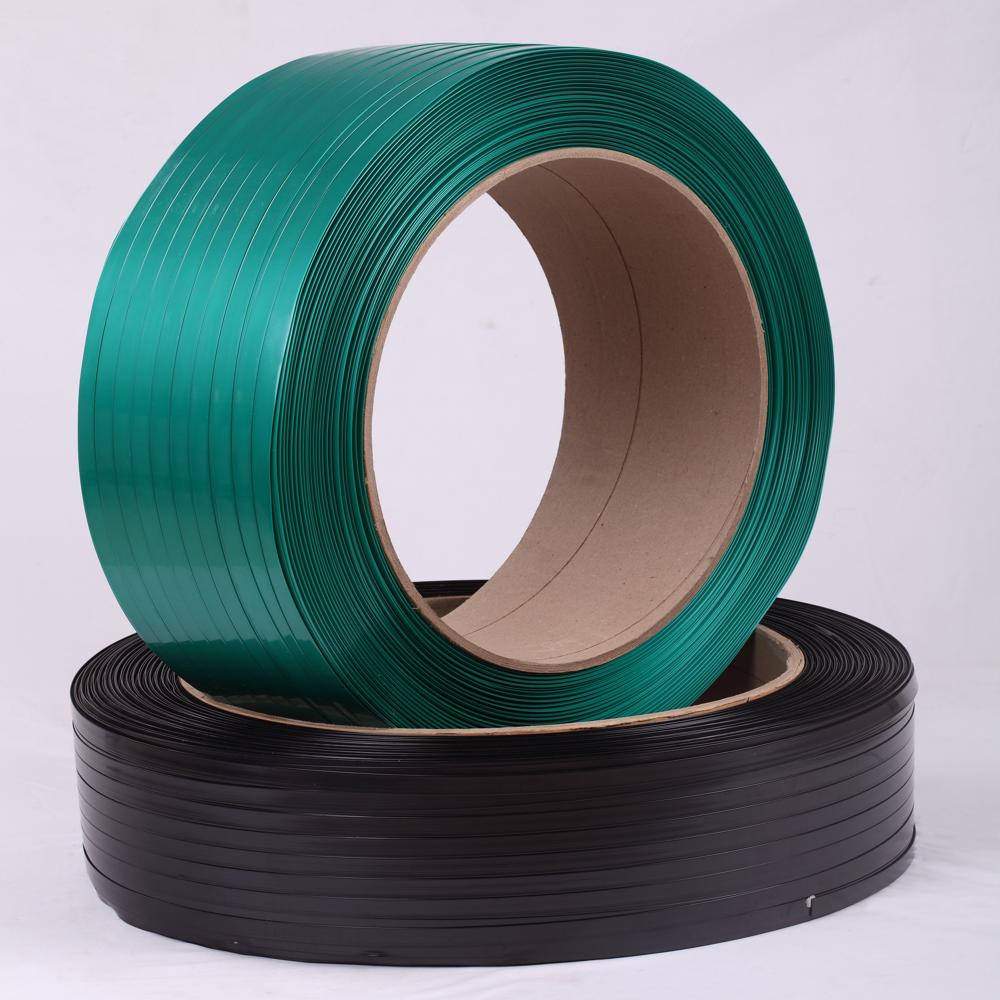

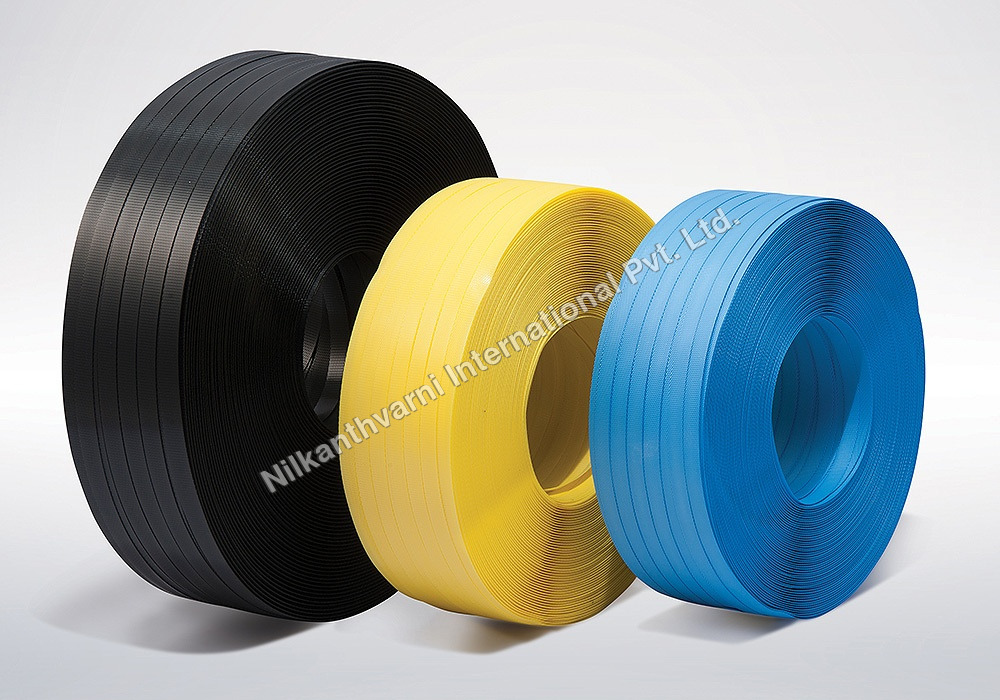

- Color CUSTOMIZE

- Material Plastic

- Size 19MM

- Thickness 0.8 Millimeter (mm)

- Water Resistant YES

- Finish Type EMBOSSED

- Print Type Flexo

- Click to View more

Corrugated Box Strap Price And Quantity

- 100 Roll

- 1100.0 INR/Roll

Corrugated Box Strap Product Specifications

- BOX PACKING

- YES

- BOX PACKING

- Flexo

- BOX PACKING

- EMBOSSED

- YES

- 8 Kilograms (kg)

- 19MM

- 0.8 Millimeter (mm)

- Plastic

- CUSTOMIZE

- 19 Millimeter (mm)

Corrugated Box Strap Trade Information

- MUNDRA

- Cash in Advance (CID), Cheque, Letter of Credit (L/C)

- 500 Roll Per Week

- 7 Days

- No

- Within a certain price range free samples are available

- BOX PACKING

- Central America, South America, Eastern Europe, Asia, Australia, North America, Western Europe, Middle East, Africa

- All India

- ISO9001-2015

Product Description

PP Strap Long Description

PP Strap, also known as Polypropylene Strapping Roll, is one of the most popular and economical strapping materials used in modern packaging industries. It is manufactured from high-quality polypropylene (PP) granules, a thermoplastic polymer known for its excellent combination of strength, flexibility, and resistance to environmental factors. The PP strap is specifically designed to meet the growing demand for secure, lightweight, and cost-effective packaging solutions across a wide range of industries such as logistics, warehousing, printing, paper, textile, food, electronics, and construction.

Material and Construction

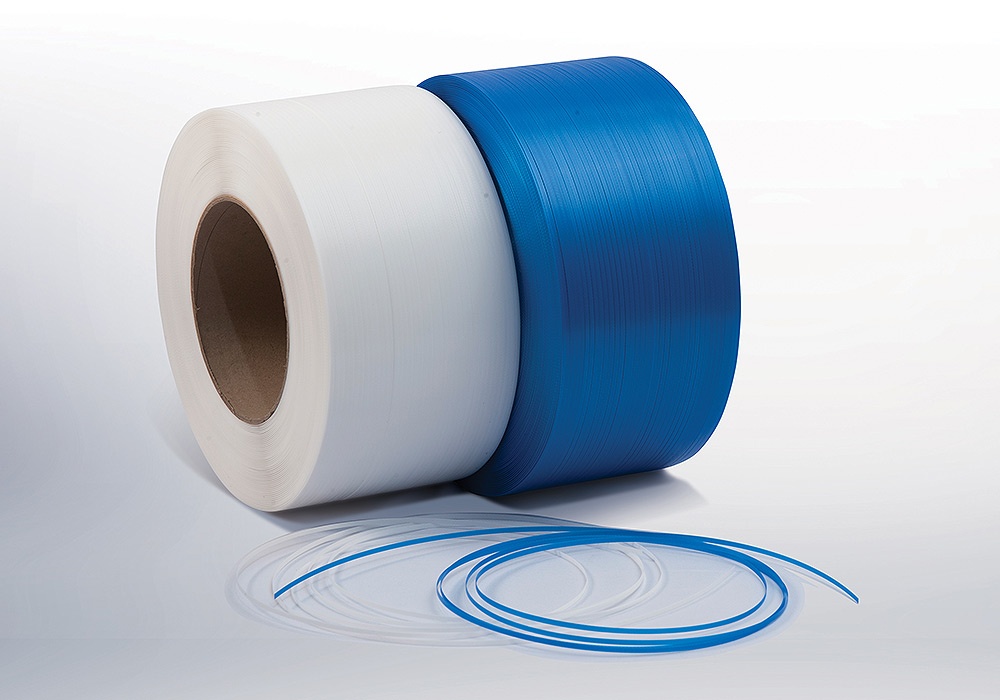

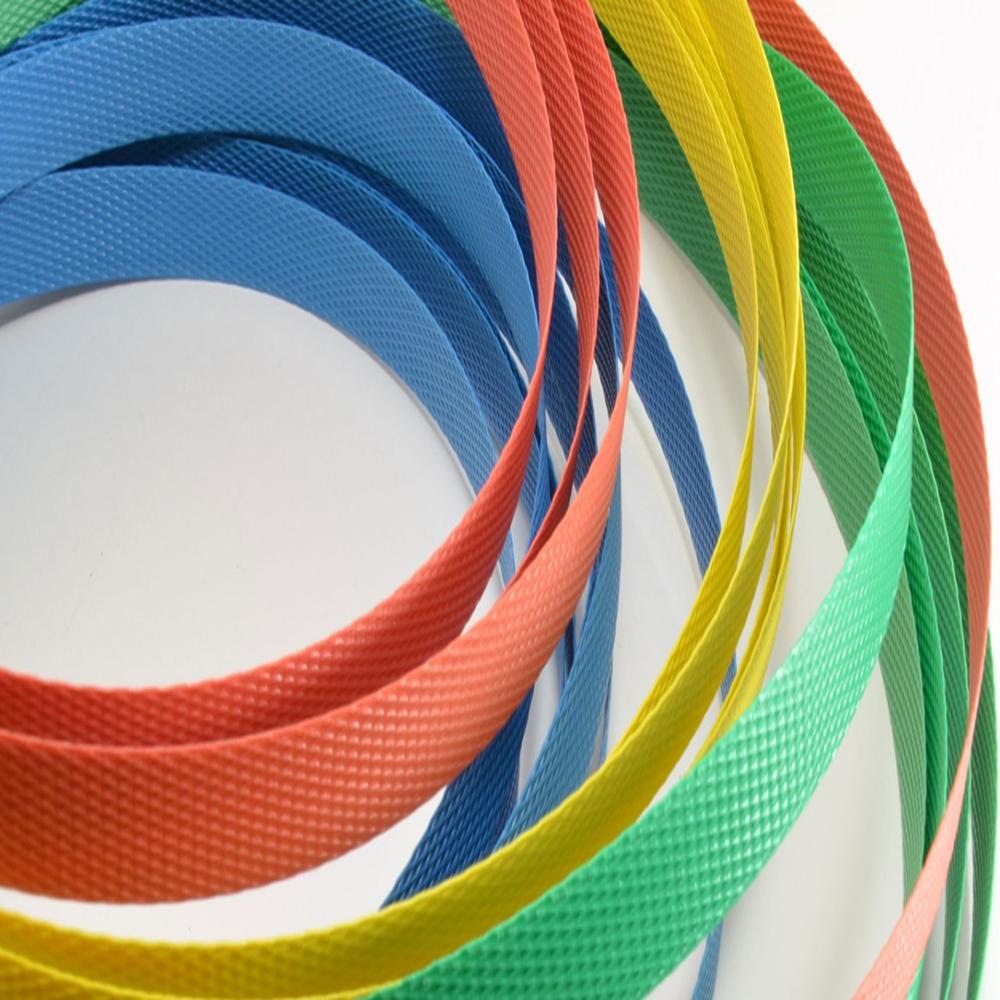

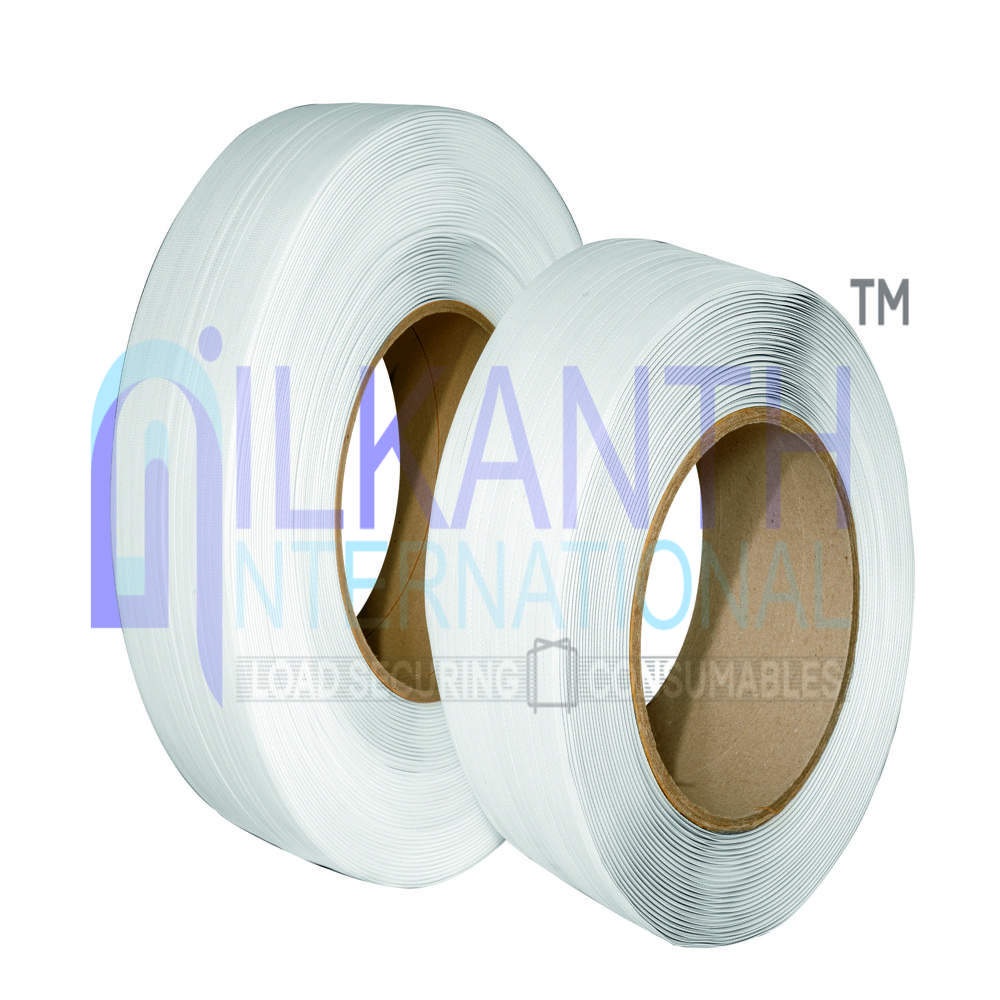

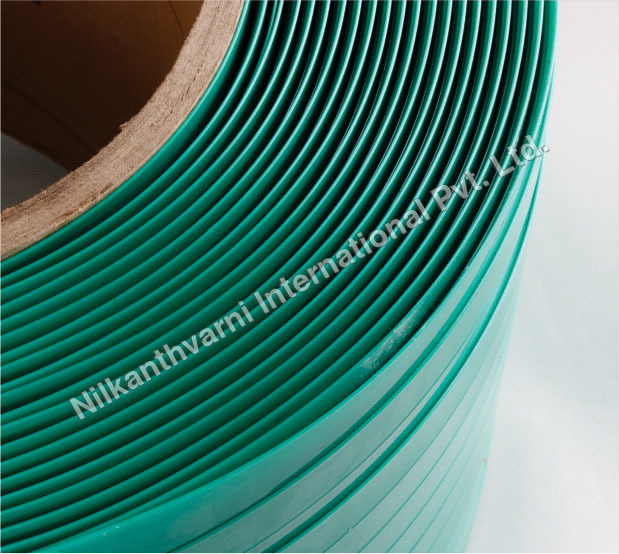

PP straps are produced using advanced extrusion technology, where the raw polypropylene resin is melted and stretched to achieve the desired strength and elasticity. These straps are available in various widths (9 mm to 19 mm), thicknesses, and colors, depending on the strapping application and machine compatibility. The surface of the strap can be smooth or embossed embossed straps offer better frictional grip, while smooth straps are ideal for high-speed automatic machines.

The Polypropylene material ensures excellent elongation properties, meaning it can stretch under tension and recover effectively, maintaining tightness during storage and transportation. The material is also lightweight, corrosion-resistant, and easy to handle, making it an efficient alternative to steel strapping for medium-duty applications.

Performance and Strength

PP strapping is designed to provide superior tensile strength and high elongation recovery, which ensures that packages remain secure even under stress or vibration during shipping. It is ideal for both manual and automatic strapping machines, and can be sealed using heat sealing, friction welding, or buckle joints.

Compared to PET and steel straps, PP straps are more cost-effective, especially for light to medium weight packaging. The controlled manufacturing process ensures consistent width, thickness, and break strength, which enhances machine performance and reduces downtime during high-speed operations.

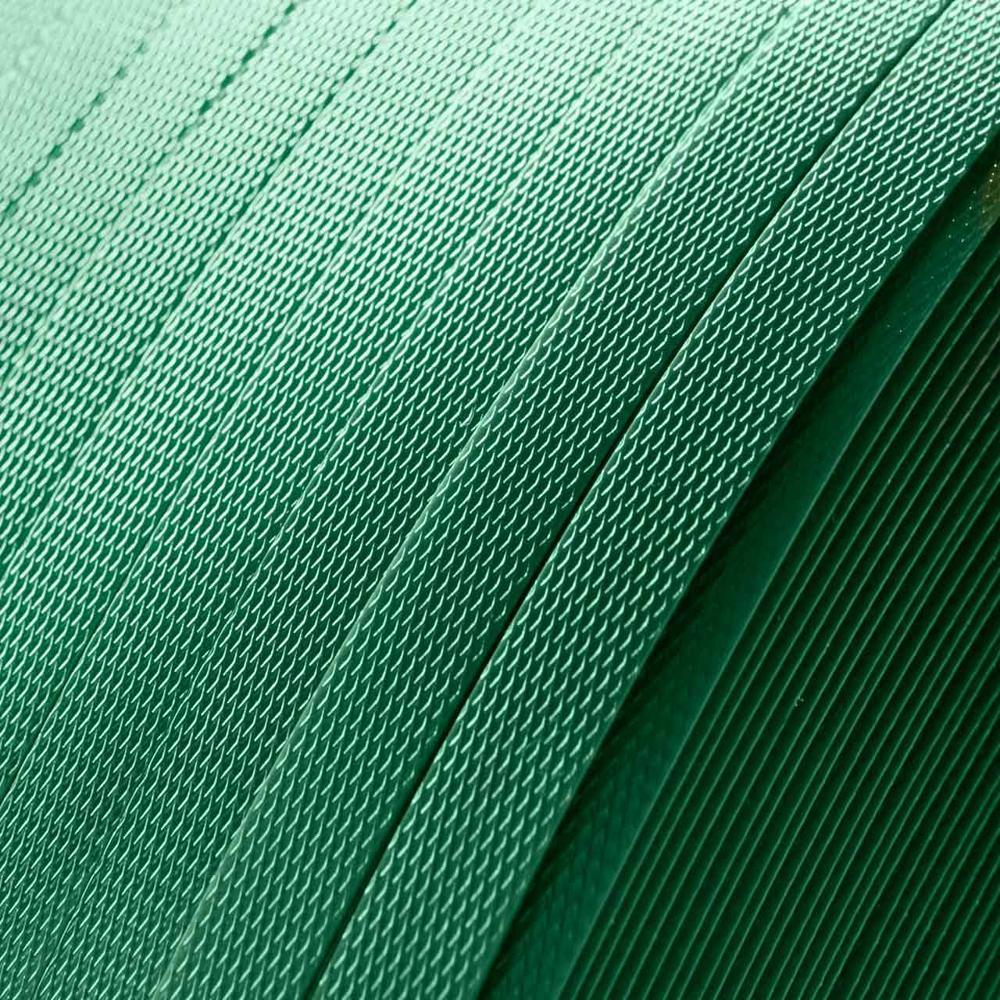

Surface and Finish Options

PP straps are available in a variety of surface finishes:

-

Embossed Finish: Provides better grip on cartons and prevents slippage.

-

Smooth Finish: Used for automatic and semi-automatic strapping machines where consistent feeding is essential.

Customers can also choose from various color options such as white, yellow, green, blue, and custom printed straps. The printed version can feature company names, logos, or handling instructions, adding branding value and helping in easy identification of products during transport.

Compatibility and Application

PP straps are compatible with manual, semi-automatic, and fully automatic strapping tools and machines. They are used for a wide range of applications, including:

-

Carton sealing and bundling

-

Palletizing goods

-

Securing corrugated boxes

-

Bundling newspapers, textiles, or pipes

-

Strapping lightweight pallets or cartons

-

Export packaging and warehousing

The versatility of PP strap makes it the preferred choice for manufacturers and distributors who require reliable packaging solutions for both domestic and export shipments.

Advantages of PP Strap

-

Lightweight and Flexible: Easy to handle, store, and use.

-

Cost-Effective: More affordable than PET or steel straps while maintaining adequate strength.

-

High Tensile Strength: Capable of securing heavy loads with minimum elongation loss.

-

Chemical and Moisture Resistant: Ideal for outdoor or humid environments.

-

Eco-Friendly: 100% recyclable material that supports sustainable packaging.

-

Safe Handling: Unlike steel strapping, PP strap does not cause injuries or rust stains.

-

Customizable: Available in various colors, sizes, and printed formats.

Manufacturing Process

The production of PP straps involves precision and quality control at every stage:

-

Raw Material Preparation: Virgin or recycled polypropylene granules are melted at controlled temperatures.

-

Extrusion: The molten material is extruded into a flat band and cooled rapidly.

-

Stretching: The cooled band is stretched to enhance its tensile strength and flexibility.

-

Embossing: A patterned roller embosses the strap to improve grip and sealing strength.

-

Winding: The finished strap is wound into rolls of specified lengths (commonly 6 kg to 8 kg rolls).

-

Quality Check: Each roll undergoes testing for break strength, elongation, and uniformity.

Environmental and Safety Aspects

As environmental awareness grows, PP straps have become a sustainable choice in the packaging world. They are 100% recyclable, free from toxic chemicals, and can be reused for secondary packaging applications. Being non-corrosive and rust-free, they also contribute to clean and safe packaging environments.

Customization and Branding

Many manufacturers offer customization options such as:

-

Custom widths and thicknesses (as per machine or product needs)

-

Color options for easy product identification

-

Printed logos, barcodes, or safety warnings

These customization options not only enhance brand visibility but also streamline logistics operations by allowing easier product classification.

Industry Applications

-

Carton Packaging: Used for bundling and sealing boxes in FMCG, retail, and export.

-

Logistics & Warehousing: Secures pallets and cartons during shipping.

-

Paper & Printing Industry: Bundling newspapers, magazines, and paper reels.

-

Food & Beverage: Suitable for carton sealing in dry and ambient environments.

-

Textile Industry: Binding fabric rolls, garments, and clothing bundles.

-

Electronics: Strapping delicate products with secure but non-damaging strength.

-

Automotive: Used for parts packaging and component logistics.

-

Construction Materials: Bundling pipes, tiles, and lightweight components.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+